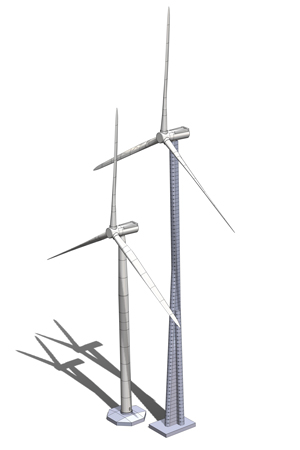

High-Altitude Modular Post-Tensioned Concrete Wind Towers

High-Altitude Modular Post-Tensioned Concrete Wind Towers

In the race for efficiency and innovation, the wind energy sector is rethinking the very shape and logistics that define its towering giants. The industry has focused on the circular shape for towers because of its low aerodynamic drag coefficient. What if, thinking outside the box, this shape were dropped from the overall design and a new approach similar to buildings was accessed? Imagine wind towers that rival the height of city landmarks, harnessing greater wind capacities while revolutionising transportation logistics. Could these giants be modular, swiftly transported like ubiquitous shipping containers, seamlessly moving across road, rail, oceans and even the skies? The challenge extends beyond mere height – it is about speed and scalability. Can wind towers be prefabricated in factories and assembled with automotive efficiency? These questions push boundaries, urging us to shatter conventional paradigms while leveraging the very strengths of standardised container logistics.

By Andrés de Antonio, Aeventor, USA

Steel tube towers, standing on average between 100 and 120 metres tall, feature conical steel sheets up to 4,000mm in diameter and 25 to 50mm thick. Transporting them requires special permits, strict schedules, and safety vehicles. Concrete, hybrid, and wood alternatives circumvent transport challenges, yet on-site assembly poses weather and structural risks, demanding heavy equipment and labour-intensive handling. A new approach for fabrication, transportation and erection is boldly needed.