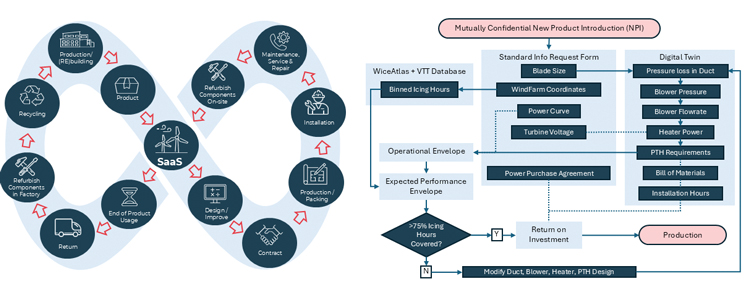

Wind turbine blade icing impacts approximately 65% of wind farms globally, leading to reduced power output, safety risks for workers and the public, and increased wear on turbine components. FabricAir has developed the BorealisWind Ice Protection System (BIPS), an innovative aftermarket solution designed to remove and prevent ice build-up on turbine blades and recover up to 75% of power losses caused by icing. The BIPS is part of FabricAir’s System as a Service model (see Figure 1), which emphasises a cyclical life-cycle approach to optimise performance while reducing the customer’s capex and minimising the product’s environmental impact. This article will use an anonymised case study to step through the life cycle of the BIPS, primarily focusing on the design tools and procedures used during inception.

By Dylan Baxter, PEng, Director of Technology for BorealisWind, FabricAir, Canada