Reducing the Cost of Energy for Larger Wind Turbines

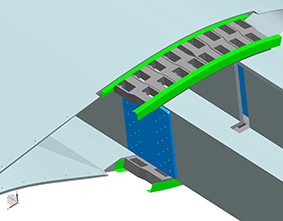

Current technical evolution within the wind energy industry seems to indicate an increase in the installed power per tower, thus leading to a need to progressively increase the length of the wind turbine blades. The IndeModular joint system is an innovative solution that overcomes the restrictions related to the manufacturing and transport of longer blades. It is a bolted connection located in the blade spar cap, where the main loads are transmitted. The joint system consists of cell units, which are pre-stressed after their assembly, resulting in a joint system under compression loads and allowing high fatigue resistance. Because of its geometry, IndeModular allows a higher supported and transmitted load than other conventional solutions, and, because of its modular concept, it can be easily integrated in the design and manufacturing of blades of different architectures and lengths by adding more or less cell units. IndeModular was successfully tested in a full-scale mechanical test to validate the joint system under the Germanischer Lloyd 2010 guidelines.

Current technical evolution within the wind energy industry seems to indicate an increase in the installed power per tower, thus leading to a need to progressively increase the length of the wind turbine blades. The IndeModular joint system is an innovative solution that overcomes the restrictions related to the manufacturing and transport of longer blades. It is a bolted connection located in the blade spar cap, where the main loads are transmitted. The joint system consists of cell units, which are pre-stressed after their assembly, resulting in a joint system under compression loads and allowing high fatigue resistance. Because of its geometry, IndeModular allows a higher supported and transmitted load than other conventional solutions, and, because of its modular concept, it can be easily integrated in the design and manufacturing of blades of different architectures and lengths by adding more or less cell units. IndeModular was successfully tested in a full-scale mechanical test to validate the joint system under the Germanischer Lloyd 2010 guidelines.

By Javier Sanz, CEO, and José Miguel Maruri, Product Manager, INDEOL, Spain

INDEOL has developed IndeModular, an advanced joint system that enables the separation of the wind turbine blade into two parts and its reassembly afterwards, therefore facilitating the manufacturing, logistics, installation and maintenance of the blade. It has been designed to have an optimal load transmission capacity and, because of its modular design, it can be integrated into any blade.