- Category: Articles

District Heating and Cooling with Thermal Storage – A Virtual Battery

District Heating and Cooling with Thermal Storage – A Virtual Battery

Wind energy is becoming a dominant renewable source, providing energy for consumers of electricity, heating and cooling. Unfortunately, few consumers can use the energy directly as the wind blows. We need storage, to avoid loss of energy.

By Anders Dyrelund, Senior Market Manager, and Søren Møller Thomsen, Energy Planner, Ramboll, Denmark

- Category: Articles

Using Probabilistic Remaining Useful Life Models to Optimise Wind Turbines

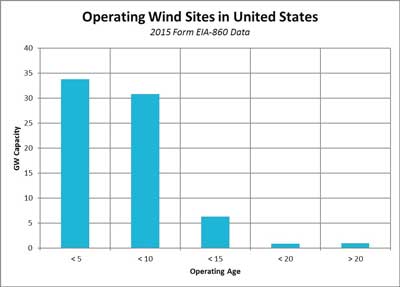

Wind turbine asset management is complex, but essential to maximise profits and maintain life cycle costs. The complexity arises for several reasons, including rapid technology development, complex supply chains and constrained infrastructure, remote locations and, more generally, lack of detailed failure data. The goal of asset management is to effectively manage corporate assets to gain maximum value, profitability and returns while safeguarding personnel, the community and the environment. A true asset integrity management programme incorporates design, maintenance, inspection, process, operations and management concepts, since all these disciplines affect the integrity of infrastructure and equipment.

Wind turbine asset management is complex, but essential to maximise profits and maintain life cycle costs. The complexity arises for several reasons, including rapid technology development, complex supply chains and constrained infrastructure, remote locations and, more generally, lack of detailed failure data. The goal of asset management is to effectively manage corporate assets to gain maximum value, profitability and returns while safeguarding personnel, the community and the environment. A true asset integrity management programme incorporates design, maintenance, inspection, process, operations and management concepts, since all these disciplines affect the integrity of infrastructure and equipment.

By Nikhil Kumar, David L. Rogers and Philip Besuner, USA

- Category: Articles

A Pilot Plant for the Production of Renewable Hydrogen

The pilot plant built within the course of the wind2hydrogen (w2h) research project is the first of this size in Austria and is unique of its kind. The main differences from other projects lie in the chosen type, design and control of the electrolyser as well as the possibility to provide multiple markets with renewable hydrogen. Current and future business cases are simulated in experimental operation from the perspective of the public power grid and the gas grid operator. With this comprehensive approach, reliable statements on the boundary conditions of the power-to-gas technology and future requirements for economic feasibility are expected.

The pilot plant built within the course of the wind2hydrogen (w2h) research project is the first of this size in Austria and is unique of its kind. The main differences from other projects lie in the chosen type, design and control of the electrolyser as well as the possibility to provide multiple markets with renewable hydrogen. Current and future business cases are simulated in experimental operation from the perspective of the public power grid and the gas grid operator. With this comprehensive approach, reliable statements on the boundary conditions of the power-to-gas technology and future requirements for economic feasibility are expected.

By Andreas Zauner and Robert Tichler, Energieinstitut an der Johannes Kepler Universität, Austria

- Category: Articles

Development, Validation and Certification of Ingeteam’s Power Converter in Suzlon’s S11x Wind Turbine

|

|

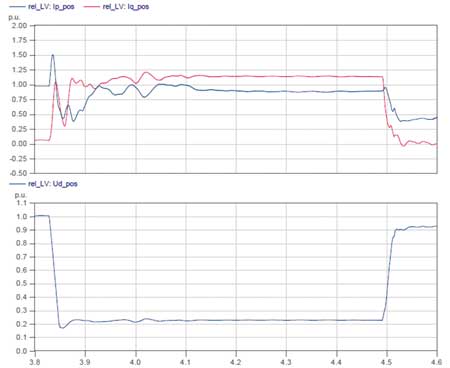

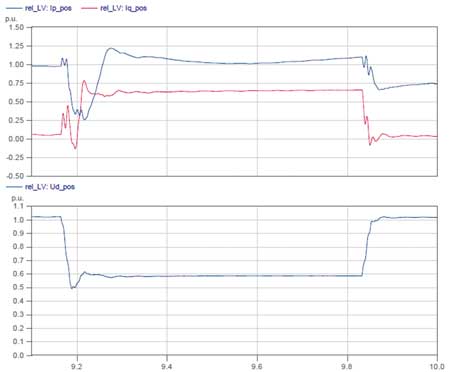

During the last 20 years, wind power’s share in electricity generation has substantially grown, making the power quality and stability of wind systems increasingly important. Consequently, the grid codes (which establish the requirements that all generation systems must fulfil in order to be allowed to connect to the grid) have been updated in order to guarantee the stability of the grid. Until the recent past, wind turbines were allowed to disconnect from the grid when transient changes in grid voltage might jeopardise the integrity of their elements, especially the power converter. However, nowadays, this is no longer allowed. Moreover, the turbines must also support the grid with active and reactive current during these transient conditions.

By Aritz Lorea, Product Manager, Wind Business, Ingeteam Power Technology, Spain

- Category: Articles

Mobile Wind Energy with Tethered Wings for Off-Grid Applications

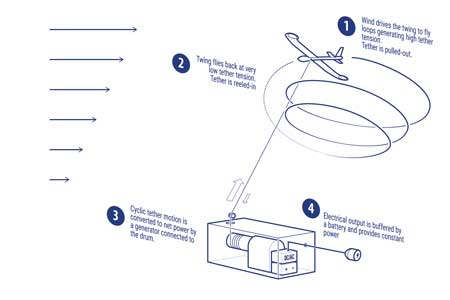

TwingTec is currently working on new wind energy technology that has the potential to unlock so far unused wind energy resources. The concept relies on a tethered wing which flies like a kite to harness the energy of wind. This enables access to winds at higher altitudes, which are typically stronger and more constant. No tower or foundation is needed, leading to an order of magnitude mass reduction compared to conventional wind turbines. The system can be containerised allowing for easy deployment. A first prototype has been built and tested. A product concept for a 100kW mobile wind energy system has been developed which addresses the needs of the off-grid market. Long-term systems in the megawatt range could contribute significantly to the global energy market.

TwingTec is currently working on new wind energy technology that has the potential to unlock so far unused wind energy resources. The concept relies on a tethered wing which flies like a kite to harness the energy of wind. This enables access to winds at higher altitudes, which are typically stronger and more constant. No tower or foundation is needed, leading to an order of magnitude mass reduction compared to conventional wind turbines. The system can be containerised allowing for easy deployment. A first prototype has been built and tested. A product concept for a 100kW mobile wind energy system has been developed which addresses the needs of the off-grid market. Long-term systems in the megawatt range could contribute significantly to the global energy market.

By Dr Rolf Luchsinger, Co-founder & CEO, TwingTec AG, Switzerland

- Category: Articles

TYER Wind’s Wind Converter

The TYER Wind vertical axis wind converter harnesses wind power using flapping wings that perfectly mimic the motion of one of the most energy-efficient birds: the hummingbird. Invented by Anis Aouini, the technology is a radical solution inspired by nature and turns out to be efficient, eco-friendly and perfectly scalable. No rotating blades; just flapping wings that convert wind power into green electricity thanks to their revolutionary 3D Aouinian kinematics.

The TYER Wind vertical axis wind converter harnesses wind power using flapping wings that perfectly mimic the motion of one of the most energy-efficient birds: the hummingbird. Invented by Anis Aouini, the technology is a radical solution inspired by nature and turns out to be efficient, eco-friendly and perfectly scalable. No rotating blades; just flapping wings that convert wind power into green electricity thanks to their revolutionary 3D Aouinian kinematics.

By Anis Aouini, Inventor, Co-founder & Chairman of TYER Wind, Tunisia

- Category: Articles

Turbine Foundations as an Opportunity for Marine Biodiversity

In view of the negative effects wind farms may have on the environment, especially during construction, the reef and reserve effects of turbine foundations (or their capacity to host diverse marine species) are often put forward as a sign of a project’s positive long-term footprint. Taking a closer look at the underlying ecological processes, there is more than meets the eye, and the potential ecological benefits of offshore wind farms go far beyond what could simply be considered as a few fish swimming around a monopile.

In view of the negative effects wind farms may have on the environment, especially during construction, the reef and reserve effects of turbine foundations (or their capacity to host diverse marine species) are often put forward as a sign of a project’s positive long-term footprint. Taking a closer look at the underlying ecological processes, there is more than meets the eye, and the potential ecological benefits of offshore wind farms go far beyond what could simply be considered as a few fish swimming around a monopile.

By Martin Perrot and Matthieu Lapinski, Seaboost, France