- Details

- Category: Articles

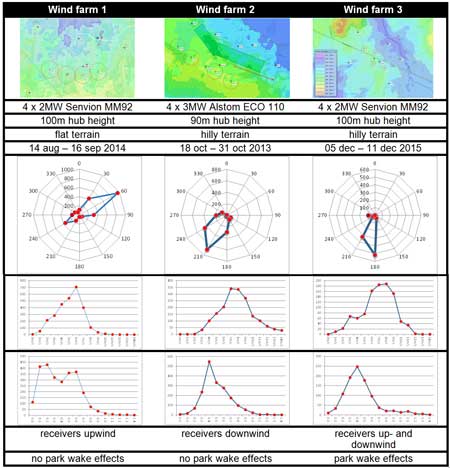

The Differences between Measured and Predicted Noise Levels from Wind Farms

The Differences between Measured and Predicted Noise Levels from Wind Farms

When planning a new wind farm, it is essential to obtain a reliable estimate of the future noise impact. An underestimation of the noise impact can lead to complaints and subsequent possible loss of efficiency due to mitigation schemes like a temporary shutdown or the use of curtailment strategies. On the other hand, an overestimation of the noise impact leads to an underdevelopment of the wind park potential.

By Luc Schillemans, Tractebel, Belgium

- Details

- Category: Articles

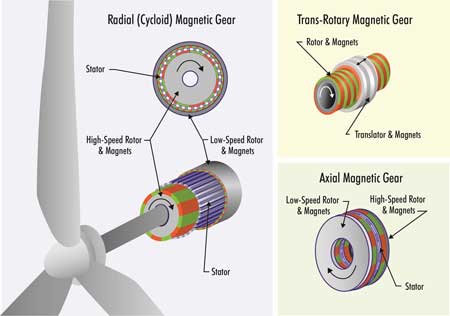

Exploring New Technologies for Extreme-Scale Turbines

Exploring New Technologies for Extreme-Scale Turbines

Larger turbines – beyond today’s multi-megawatt onshore and offshore machines – are one of the most attractive options for reducing the cost of wind energy. Continued technology scale-up to rated capacities of 10MW and beyond requires novel concepts for overcoming the fundamental limitations of today’s turbine designs and materials, including structural constraints of drive-train components. This article explores how magnetic gearbox technologies could provide solutions.

By Luis Cerezo, Technical Executive, EPRI, USA

- Details

- Category: Articles

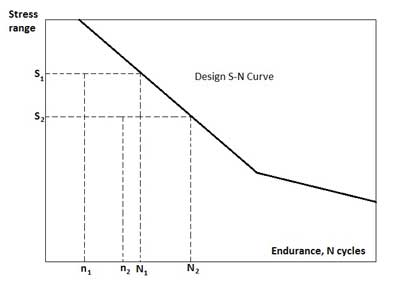

How to Calculate the Remaining Useful Life (RUL) of Wind Farms

How to Calculate the Remaining Useful Life (RUL) of Wind Farms

Wind farms are part of our surroundings and therefore are in general fairly accessible power generation facilities. Safety is key to both continuation of operations and a corporate responsibility towards workers and third parties. It must be safeguarded through a comprehensive process including analytical RUL calculation, inspections and certification to confirm that there is a limited risk exposure while the installation continues operating. Once the real status of the wind turbines is characterised, smart operational strategies can be deployed to maximise the return on the investment.

By Jose Javier Ripa, Business Development Manager, UL DEWI, Spain

- Details

- Category: Articles

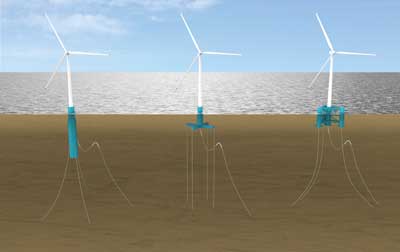

Reducing Cost and Risk in Floating Offshore Wind

In recent years, floating wind has gradually matured as a technology, progressing from being the subject of academic research to a handful of full-scale, stand-alone prototype projects (Hywind in Scotland, Principle Power in Portugal and the FORWARD project in Japan), to the development of multiple pre-commercial arrays. Technological advances in floating wind will open up opportunities to exploit the abundant wind resource in deeper water sites where it is currently not possible to deploy fixed-bottom foundations, making this an important area of research for the offshore wind industry. This article analyses the costs and risks of the three most common types of floating wind structure and compares them to those of a fixed-bottom monopile wind farm. It also provides an outlook on the technology’s future and notes areas where further research is needed.

In recent years, floating wind has gradually matured as a technology, progressing from being the subject of academic research to a handful of full-scale, stand-alone prototype projects (Hywind in Scotland, Principle Power in Portugal and the FORWARD project in Japan), to the development of multiple pre-commercial arrays. Technological advances in floating wind will open up opportunities to exploit the abundant wind resource in deeper water sites where it is currently not possible to deploy fixed-bottom foundations, making this an important area of research for the offshore wind industry. This article analyses the costs and risks of the three most common types of floating wind structure and compares them to those of a fixed-bottom monopile wind farm. It also provides an outlook on the technology’s future and notes areas where further research is needed.

By Robert Proskovics and Gavin Smart, ORE Catapult, Glasgow, UK

- Details

- Category: Articles

Anticipating Quarterly Winds and Revenues One Month Ahead

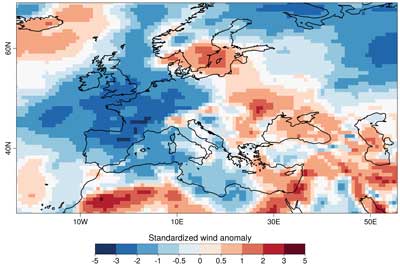

The wind power industry has traditionally used fixed climatologies for anticipating wind speed and wind generation beyond 15 days ahead. However, wind is highly variable at monthly and seasonal scales, and anomalies occur around the globe every now and then. Assuming that future conditions will be similar to average past conditions has several inherent shortcomings. Recent advances in dynamical modelling systems have opened new opportunities for seasonal prediction of wind speed that can improve current practices. Ensemble ocean–atmosphere numerical simulations can provide meaningful forecasts that indicate the probability of having above-normal, normal or below-normal wind conditions in the next season with one month of advance warning. Through an analysis of some case studies we will explore in this article how seasonal predictions of wind speed and generation have been made possible, what their quality is and how they can help in the decision-making processes for practical applications.

The wind power industry has traditionally used fixed climatologies for anticipating wind speed and wind generation beyond 15 days ahead. However, wind is highly variable at monthly and seasonal scales, and anomalies occur around the globe every now and then. Assuming that future conditions will be similar to average past conditions has several inherent shortcomings. Recent advances in dynamical modelling systems have opened new opportunities for seasonal prediction of wind speed that can improve current practices. Ensemble ocean–atmosphere numerical simulations can provide meaningful forecasts that indicate the probability of having above-normal, normal or below-normal wind conditions in the next season with one month of advance warning. Through an analysis of some case studies we will explore in this article how seasonal predictions of wind speed and generation have been made possible, what their quality is and how they can help in the decision-making processes for practical applications.

By Llorenç Lledó, Barcelona Supercomputing Center, Barcelona

- Details

- Category: Articles

A Revolutionary Concept Featuring a Ring-Shaped Generator

Members of the MegaWindForce (MWF) team developed a highly efficient variable transmission system back in 2012. While researching whether this invention would contribute to the efficiency of wind turbines they became aware of the catch 22 situation of the wind industry: rotors need to be bigger to harvest more energy, resulting in lower numbers of revolutions, which makes the design of generators more complex and relatively more expensive. A new concept was developed, where the main shaft was replaced by a ring. This revolutionary concept resulted in several patents.

Members of the MegaWindForce (MWF) team developed a highly efficient variable transmission system back in 2012. While researching whether this invention would contribute to the efficiency of wind turbines they became aware of the catch 22 situation of the wind industry: rotors need to be bigger to harvest more energy, resulting in lower numbers of revolutions, which makes the design of generators more complex and relatively more expensive. A new concept was developed, where the main shaft was replaced by a ring. This revolutionary concept resulted in several patents.

By Ton Bos, co-founder and shareholder of MegaWindForce, The Netherlands

- Details

- Category: Articles

Life-cycle Engineering Asset Management

International research and engineering solutions company TWI Ltd has set its sights on harnessing digital twin technology to transform the process of monitoring and maintaining offshore wind turbines. TWI has built up its knowledge in the structural health and condition monitoring of wind turbines in recent years as a result of its participation in a number of European and UK collaborative projects, including CMSWind, WTBMonitor and TOWERPOWER.

International research and engineering solutions company TWI Ltd has set its sights on harnessing digital twin technology to transform the process of monitoring and maintaining offshore wind turbines. TWI has built up its knowledge in the structural health and condition monitoring of wind turbines in recent years as a result of its participation in a number of European and UK collaborative projects, including CMSWind, WTBMonitor and TOWERPOWER.

By Ángela Angulo, Senior Project Leader, TWI Ltd, UK