- Category: Articles

The Concept and its Potential

After ten years of dedicated and innovative technology development 'Bucket Foundations' are now being 'rolled out' into the commercial market. The expectations are that this concept will reduce the cost of energy, especially when that energy is to be produced in deeper waters.

After ten years of dedicated and innovative technology development 'Bucket Foundations' are now being 'rolled out' into the commercial market. The expectations are that this concept will reduce the cost of energy, especially when that energy is to be produced in deeper waters.

By Henrik L. Nielsen, Universal Foundation, Denmark

{access view=!registered}Only logged in users can view the full text of the article.{/access}{access view=registered}The Bucket Foundation concept combines the benefits and main proven assets of a gravity base foundation, with a monopile and a suction bucket. Importantly the design also includes a patented installation system, which controls the vertical alignment of the total foundation as it sucks itself into the seabed, reducing the overall installation time significantly.

In brief, these new foundations consist of an up-ended bucket, which, via a closing lid is connected to a shaft that, in turn, connects to the wind turbine tower, met mast or other offshore surface installation. Once installed the ‘bucket’ encloses a large volume of sediment, which helps provide a high load-bearing capacity (see Figure1).

The development of this new concept began back in 2001 at Aalborg University, Denmark, with analytical studies, numerical modelling and laboratory tests that eventually led to pit tests of 2 x 2 metre and 4 x 4 metre buckets. Installation methods and techniques were developed from these prototypes using suction and skirt-tip injection. The installation of Bucket Foundations can be divided into two phases: (1) self-penetration of the bucket and (2) penetration of the bucket by means of suction. In phase 1 the skirt penetrates into the seabed by gravity. In phase 2 the penetration is increased by applying suction to the inside of the ‘bucket’. The suction creates an upward flow in the sediments within the ‘bucket’, reducing the effective stresses in the sediments beneath the skirt edge, and results in a net downward force on the top of the bucket, as illustrated in Figure 2.

The reduction in effective stresses greatly reduces the penetration resistance, allowing the skirt to penetrate the sediments further. The suction applied is limited by the gradient that causes piping channels in the soil within the bucket (i.e. the critical gradient at which the effective stress equals 0). Once piping channels are created the suction can no longer be sustained. If the suction is kept at a minimum, and does not cause piping in the soil, the soil will regain its strength when pumping is ceased. The critical gradient , where gw is the unit weight of water and g' is the submerged unit weight. The exit hydraulic gradient i can also be expressed in terms of the applied suction p and the seepage length s as . The critical suction resulting in formation of local piping channels is therefore . Combining these formulae with empirical experience the critical suction can be expressed as , where D is the diameter of the bucket, and h is the penetrated length of the skirt. Thus, if h is known, the critical suction can be controlled.

In 2002 the first full-scale Bucket Foundation was installed using the suction technique. A Vestas V90, 3MW turbine was erected on top of a full-scale prototype of the Bucket Foundation, with a diameter, D, of 14 metres, and a skirt height, d, of 6 metres. The turbine is still in production, and now, after nearly ten years of performance data has been acquired, it is possible to say that 'Bucket Foundations' are one of the most proven foundation technologies available.

In 2009 a Bucket Foundation was installed at Horns Rev 2 as support for a met mast. Here the suction installation technology was reversed as a tilt of approximately 1 degree out of vertical was reduced to less than 0.1 of a degree. The ‘bucket’ was simply lifted 1 metre and reinstalled within the given tolerances (see Figure 3).

In conjunction with the installation requirements given above, geotechnical and structural design will cover all the limit states of Bucket Foundations under combined loads from wind, waves and currents. From these considerations a design approach can be developed covering the basic design, followed by a conceptual design, and finally a detailed design. This design procedure is verified by DNV, to fulfil the requirements given in the Offshore Standard DNV-OS- J101, 'Design of Offshore Wind Turbine Structures'.

The flexibility of these foundations lies in the variety of possible designs, and this has a direct bearing on the ‘universal’ prospects of the concept. Depending on the actual ground, meteorological and ocean conditions and the load regime, the bucket skirt height (d), the diameter (D), and shaft dimensions can be varied to give the optimal material usage and still provide an adequate bearing capacity and stiffness as required by the integrated turbine foundation system.

Recent participation in the Carbon Trust foundation competition – Offshore Wind Accelerator – yielded a promising result: 'Bucket Foundations' were chosen as one of the winning concepts out of a total of 104 entries. 'Bucket Foundations' show an estimated cost reduction for a final installed foundation of 15–30% over other competitor systems.

With a strong industry player involved as the major shareholder, the potential now exists for introducing 'Bucket Foundations' as the solution for large-scale wind farms. 'Bucket Foundations' are aimed directly at the offshore wind energy sector, enhancing technical performance while also reducing the significant costs for offshore foundation installations. With the acquisition of Universal Foundation, Fred. Olsen related companies are now positioned to provide a full, packaged solution for offshore wind farm foundations – from feasibility study/design to the finished installation of an integrated system of foundation and turbine.

About Universal Foundation

First Olsen, the engineering arm of Scandinavian shipping firm Fred. Olsen, acquired 60% of the Danish company Universal Foundation A/S (formerly known as MBD Offshore Power A/S) in August 2011. The remaining interests in Universal Foundation are held by the Danish utility company DONG Energy Power Holding A/S, Novasion ApS and Aalborg University, with whom the concept foundations were developed and tested.{/access}

After ten years of dedicated and innovative technology development 'Bucket Foundations' are now being 'rolled out' into the commercial market. The expectations are that this concept will reduce the cost of energy, especially when that energy is to be produced in deeper waters.

After ten years of dedicated and innovative technology development 'Bucket Foundations' are now being 'rolled out' into the commercial market. The expectations are that this concept will reduce the cost of energy, especially when that energy is to be produced in deeper waters.By Henrik L. Nielsen, Universal Foundation, Denmark

{access view=!registered}Only logged in users can view the full text of the article.{/access}{access view=registered}The Bucket Foundation concept combines the benefits and main proven assets of a gravity base foundation, with a monopile and a suction bucket. Importantly the design also includes a patented installation system, which controls the vertical alignment of the total foundation as it sucks itself into the seabed, reducing the overall installation time significantly.

In brief, these new foundations consist of an up-ended bucket, which, via a closing lid is connected to a shaft that, in turn, connects to the wind turbine tower, met mast or other offshore surface installation. Once installed the ‘bucket’ encloses a large volume of sediment, which helps provide a high load-bearing capacity (see Figure1).

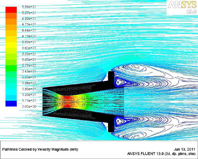

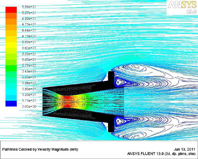

The development of this new concept began back in 2001 at Aalborg University, Denmark, with analytical studies, numerical modelling and laboratory tests that eventually led to pit tests of 2 x 2 metre and 4 x 4 metre buckets. Installation methods and techniques were developed from these prototypes using suction and skirt-tip injection. The installation of Bucket Foundations can be divided into two phases: (1) self-penetration of the bucket and (2) penetration of the bucket by means of suction. In phase 1 the skirt penetrates into the seabed by gravity. In phase 2 the penetration is increased by applying suction to the inside of the ‘bucket’. The suction creates an upward flow in the sediments within the ‘bucket’, reducing the effective stresses in the sediments beneath the skirt edge, and results in a net downward force on the top of the bucket, as illustrated in Figure 2.

The reduction in effective stresses greatly reduces the penetration resistance, allowing the skirt to penetrate the sediments further. The suction applied is limited by the gradient that causes piping channels in the soil within the bucket (i.e. the critical gradient at which the effective stress equals 0). Once piping channels are created the suction can no longer be sustained. If the suction is kept at a minimum, and does not cause piping in the soil, the soil will regain its strength when pumping is ceased. The critical gradient , where gw is the unit weight of water and g' is the submerged unit weight. The exit hydraulic gradient i can also be expressed in terms of the applied suction p and the seepage length s as . The critical suction resulting in formation of local piping channels is therefore . Combining these formulae with empirical experience the critical suction can be expressed as , where D is the diameter of the bucket, and h is the penetrated length of the skirt. Thus, if h is known, the critical suction can be controlled.

In 2002 the first full-scale Bucket Foundation was installed using the suction technique. A Vestas V90, 3MW turbine was erected on top of a full-scale prototype of the Bucket Foundation, with a diameter, D, of 14 metres, and a skirt height, d, of 6 metres. The turbine is still in production, and now, after nearly ten years of performance data has been acquired, it is possible to say that 'Bucket Foundations' are one of the most proven foundation technologies available.

In 2009 a Bucket Foundation was installed at Horns Rev 2 as support for a met mast. Here the suction installation technology was reversed as a tilt of approximately 1 degree out of vertical was reduced to less than 0.1 of a degree. The ‘bucket’ was simply lifted 1 metre and reinstalled within the given tolerances (see Figure 3).

In conjunction with the installation requirements given above, geotechnical and structural design will cover all the limit states of Bucket Foundations under combined loads from wind, waves and currents. From these considerations a design approach can be developed covering the basic design, followed by a conceptual design, and finally a detailed design. This design procedure is verified by DNV, to fulfil the requirements given in the Offshore Standard DNV-OS- J101, 'Design of Offshore Wind Turbine Structures'.

The flexibility of these foundations lies in the variety of possible designs, and this has a direct bearing on the ‘universal’ prospects of the concept. Depending on the actual ground, meteorological and ocean conditions and the load regime, the bucket skirt height (d), the diameter (D), and shaft dimensions can be varied to give the optimal material usage and still provide an adequate bearing capacity and stiffness as required by the integrated turbine foundation system.

Recent participation in the Carbon Trust foundation competition – Offshore Wind Accelerator – yielded a promising result: 'Bucket Foundations' were chosen as one of the winning concepts out of a total of 104 entries. 'Bucket Foundations' show an estimated cost reduction for a final installed foundation of 15–30% over other competitor systems.

With a strong industry player involved as the major shareholder, the potential now exists for introducing 'Bucket Foundations' as the solution for large-scale wind farms. 'Bucket Foundations' are aimed directly at the offshore wind energy sector, enhancing technical performance while also reducing the significant costs for offshore foundation installations. With the acquisition of Universal Foundation, Fred. Olsen related companies are now positioned to provide a full, packaged solution for offshore wind farm foundations – from feasibility study/design to the finished installation of an integrated system of foundation and turbine.

About Universal Foundation

First Olsen, the engineering arm of Scandinavian shipping firm Fred. Olsen, acquired 60% of the Danish company Universal Foundation A/S (formerly known as MBD Offshore Power A/S) in August 2011. The remaining interests in Universal Foundation are held by the Danish utility company DONG Energy Power Holding A/S, Novasion ApS and Aalborg University, with whom the concept foundations were developed and tested.{/access}

- Category: Articles

Fluid Dynamics Optimisation of an Innovative Aerogenerator: PAULA

During recent years, the enormous increase in wind energy exploitation has highlighted the need for innovative conversion technologies able to concentrate power production in the areas with both a good wind potential and plenty of space availability. With these requirements in mind, many interesting solutions have been developed for offshore wind turbines, but currently there are very few innovative proposals for the utilisation of the potential of high-altitude winds.

During recent years, the enormous increase in wind energy exploitation has highlighted the need for innovative conversion technologies able to concentrate power production in the areas with both a good wind potential and plenty of space availability. With these requirements in mind, many interesting solutions have been developed for offshore wind turbines, but currently there are very few innovative proposals for the utilisation of the potential of high-altitude winds.

By F. Castellani, University of Perugia, M. Marchionni, University of Calabria and P. Boldrin, ‘Under The Etruscan Sun’ project, Italy

During recent years, the enormous increase in wind energy exploitation has highlighted the need for innovative conversion technologies able to concentrate power production in the areas with both a good wind potential and plenty of space availability. With these requirements in mind, many interesting solutions have been developed for offshore wind turbines, but currently there are very few innovative proposals for the utilisation of the potential of high-altitude winds.

During recent years, the enormous increase in wind energy exploitation has highlighted the need for innovative conversion technologies able to concentrate power production in the areas with both a good wind potential and plenty of space availability. With these requirements in mind, many interesting solutions have been developed for offshore wind turbines, but currently there are very few innovative proposals for the utilisation of the potential of high-altitude winds.By F. Castellani, University of Perugia, M. Marchionni, University of Calabria and P. Boldrin, ‘Under The Etruscan Sun’ project, Italy

- Category: Articles

Techniques to Put Your Data to Work for You

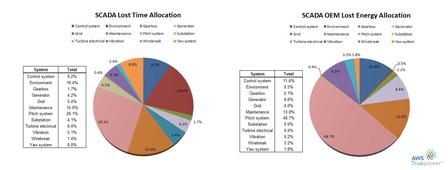

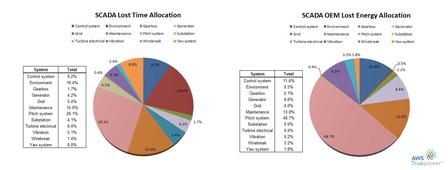

Wind plants generate enormous amounts of data which, if utilised properly, can provide significant insight for operational improvements, resulting in more proactive plant management, and a better return on investments. In order to effectively and efficiently utilise the plant data, it becomes necessary to employ a variety of analysis techniques. These techniques could be simple signal comparisons or the calculation of advanced key performance indicators. In either case, the end goal remains the same: to give plant operators tools and techniques which will utilise the data currently available at a wind plant to optimise plant performance.

Wind plants generate enormous amounts of data which, if utilised properly, can provide significant insight for operational improvements, resulting in more proactive plant management, and a better return on investments. In order to effectively and efficiently utilise the plant data, it becomes necessary to employ a variety of analysis techniques. These techniques could be simple signal comparisons or the calculation of advanced key performance indicators. In either case, the end goal remains the same: to give plant operators tools and techniques which will utilise the data currently available at a wind plant to optimise plant performance.

By Paul Legac, Applications Engineer, AWS Truepower, USA

Wind plants generate enormous amounts of data which, if utilised properly, can provide significant insight for operational improvements, resulting in more proactive plant management, and a better return on investments. In order to effectively and efficiently utilise the plant data, it becomes necessary to employ a variety of analysis techniques. These techniques could be simple signal comparisons or the calculation of advanced key performance indicators. In either case, the end goal remains the same: to give plant operators tools and techniques which will utilise the data currently available at a wind plant to optimise plant performance.

Wind plants generate enormous amounts of data which, if utilised properly, can provide significant insight for operational improvements, resulting in more proactive plant management, and a better return on investments. In order to effectively and efficiently utilise the plant data, it becomes necessary to employ a variety of analysis techniques. These techniques could be simple signal comparisons or the calculation of advanced key performance indicators. In either case, the end goal remains the same: to give plant operators tools and techniques which will utilise the data currently available at a wind plant to optimise plant performance.By Paul Legac, Applications Engineer, AWS Truepower, USA

- Category: Articles

The Advantages of a Square Rigged Sail Design

Currently, the most common method for harnessing wind energy has been to use horizontal-axis wind turbines. However, they have certain inherent disadvantages. Vertical-axis wind turbines overcome some of these disadvantages but many designs introduce problems of their own. After summarising the disadvantages and advantages of past and current designs of both horizontal and vertical-axis turbines, the author introduces the idea of a square rigged sail wind turbine, which he feels has greater utility than previous designs.

Currently, the most common method for harnessing wind energy has been to use horizontal-axis wind turbines. However, they have certain inherent disadvantages. Vertical-axis wind turbines overcome some of these disadvantages but many designs introduce problems of their own. After summarising the disadvantages and advantages of past and current designs of both horizontal and vertical-axis turbines, the author introduces the idea of a square rigged sail wind turbine, which he feels has greater utility than previous designs.

By Jon Howard, Research Specialist, H Energy Innovations, USA

Description of 'Prior Art'

{access view=!registered}Only logged in users can view the full text of the article.{/access}{access view=registered}Wind power has been a source of energy for centuries; however, there have always been distinctly different approaches as to how to extract that energy. In particular, there have been both horizontal-axis and vertical-axis wind turbines. In these modern times, the most common method for harnessing wind energy has been to use a horizontal-axis wind turbine. While horizontal-axis wind turbines have been promoted as being the more efficient type compared to other methods, they present several disadvantages. For instance, horizontal-axis wind turbines have to be turned into the wind to start functioning. Also, they have a relatively high cut-in wind speed for operation and a low cut-out wind speed. This allows for only a relatively narrow window of operation, beyond which they are prone to damage. Another problem associated with the horizontal-axis design is that they optimally require a near gale force wind to produce power. Further, horizontal-axis wind turbines can be extremely high above a ground surface, making it difficult for technicians to perform repairs. Due to such heights, technicians are often exposed to grave risks as they provide maintenance in adverse weather conditions.

Alternatives to Traditional Designs

Vertical-axis wind turbines change the axis of rotation of the turbine. These offer an alternative to the traditional wind turbine. The vertical-axis wind turbines improve the safety of servicing and maintenance duties because services are performed much closer to the ground. In the 1920s, a French inventor by the name of Georges Jean Marie Darrieus designed a vertical-axis wind turbine that has been referred to as the ‘Darrieus design’ or ‘eggbeater’. The Darrieus design uses a series of sails that are fixed at a set angle and arranged symmetrically around a vertical axis. The symmetry of the sails provides a very effective means of generating a rotational force to the vertical shaft axis. These types of vertical-axis wind turbines are used today on tall buildings to utilise the high wind velocity found at higher altitudes. Unfortunately, sail fatigue, which causes premature failure of the system, is a common problem associated with the Darrieus design.

As an alternative to the Darrieus design, the US Patent No. 4,449,053, issued to Kutcher, shows a vertical-axis wind turbine that uses vertically positioned rotor blades. Blades are connected both at the top and bottom of a vertically extending rotor tube. While the Kutcher design reduces sail fatigue, the vertically positioned rotor blades do not easily capture wind at all angles, thereby reducing their effectiveness.

Other Vertical-Axis Designs

Another variation is the Giromill Cycloturbine, shown in US Patent No. 7,315,093, issued to Graham. The Giromill Cycloturbine has sails mounted such that the sails can rotate around an axis. The design of the Cycloturbine allows the sails to be pitched such that the sails are always at an angle relative to the wind. A main advantage to this design is that the torque generated remains almost constant over a fairly wide angle. Therefore, a Cycloturbine with three or four sails has a fairly constant torque. Predetermining the range of angles, the torque approaches a possible maximum torque, wherein the system generates more power. The system also has the advantage of being able to self start by pitching the down-wind moving sails flat to the wind to generate drag and start the turbine spinning at a low speed. One drawback to this design is that the sail pitching mechanism is complex and generally heavy, and a wind direction sensor must be added to the design in order to properly pitch the sails.

Current Designs

Currently, the commercial application of wind energy harnessing is primarily, if not exclusively, horizontal-axis wind turbines, even though vertical-axis wind turbines avoid most of the disadvantages inherent in the horizontal-axis design. For example, vertical-axis wind turbines are omni-directional and have a lower cut-in wind speed and higher cut-out speed, thus making the window of operation wider. Also, vertical-axis wind turbines can have components that need servicing located at the bottom end of the structure making access more convenient. Vertical-axis wind turbines also allow for lower-ratio gearboxes, which are less expensive and more efficient than the gearboxes needed to operate horizontal-axis wind turbines, Further, vertical-axis wind turbines are able to operate at a higher wind speed and at lower risk of suffering wind damage. Finally, vertical-axis wind turbines are more suited to a simpler design and construction.

Thus, there is a continuing need for a vertical-axis wind turbine that captures the inherent advantages of the vertical-axis design, yet improves upon the drawbacks of existing vertical-axis designs.

Summary of Findings

The conclusion that was drawn from studying previous designs in this field was that an improved version, without the drawbacks of the previous models, could be created by using reinforced square rigged sails fixed at a 90 degree angle, at the tip of parallel and horizontal yardarms. Such a design is described below.

Square Rigged Sail Wind Turbine

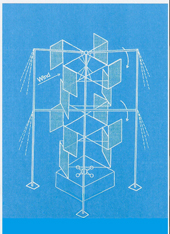

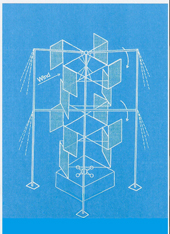

The suggested new wind turbine is a vertical axis turbine designed to generate electricity at both onshore and offshore locations. The turbine is driven by a square rigged sail conformation that can include one or more stacked sail assemblies. Each sail assembly includes a main shaft having a vertical axis of rotation, with each successive sail assembly in the stack sharing the main shaft. Each sail assembly includes one or more yardarms that extend horizontally from the main shaft. The sails are attached to the yardarms such that the main shaft is central and positioned between the sails.

From the top down in the blue diagram (figure 1), the second and fourth sail assemblies are obscured showing two sails only for each. Also, the entire rear vertical column, the vertical main shaft axis, and corner bracing on the lower three sail assemblies are obscured in this diagram.

Biography of the Author

Since 2007, Jon Howard has been a research specialist, for H Energy Innovations, in

southern California, USA, where extensive studies have been conducted in wind energy. Mr Howard’s research on wind energy development and studies in meteorology and the environment has led him to create a vertical-axis wind turbine with greater utility advantage than the previous designs.{/access}

Currently, the most common method for harnessing wind energy has been to use horizontal-axis wind turbines. However, they have certain inherent disadvantages. Vertical-axis wind turbines overcome some of these disadvantages but many designs introduce problems of their own. After summarising the disadvantages and advantages of past and current designs of both horizontal and vertical-axis turbines, the author introduces the idea of a square rigged sail wind turbine, which he feels has greater utility than previous designs.

Currently, the most common method for harnessing wind energy has been to use horizontal-axis wind turbines. However, they have certain inherent disadvantages. Vertical-axis wind turbines overcome some of these disadvantages but many designs introduce problems of their own. After summarising the disadvantages and advantages of past and current designs of both horizontal and vertical-axis turbines, the author introduces the idea of a square rigged sail wind turbine, which he feels has greater utility than previous designs.By Jon Howard, Research Specialist, H Energy Innovations, USA

Description of 'Prior Art'

{access view=!registered}Only logged in users can view the full text of the article.{/access}{access view=registered}Wind power has been a source of energy for centuries; however, there have always been distinctly different approaches as to how to extract that energy. In particular, there have been both horizontal-axis and vertical-axis wind turbines. In these modern times, the most common method for harnessing wind energy has been to use a horizontal-axis wind turbine. While horizontal-axis wind turbines have been promoted as being the more efficient type compared to other methods, they present several disadvantages. For instance, horizontal-axis wind turbines have to be turned into the wind to start functioning. Also, they have a relatively high cut-in wind speed for operation and a low cut-out wind speed. This allows for only a relatively narrow window of operation, beyond which they are prone to damage. Another problem associated with the horizontal-axis design is that they optimally require a near gale force wind to produce power. Further, horizontal-axis wind turbines can be extremely high above a ground surface, making it difficult for technicians to perform repairs. Due to such heights, technicians are often exposed to grave risks as they provide maintenance in adverse weather conditions.

Alternatives to Traditional Designs

Vertical-axis wind turbines change the axis of rotation of the turbine. These offer an alternative to the traditional wind turbine. The vertical-axis wind turbines improve the safety of servicing and maintenance duties because services are performed much closer to the ground. In the 1920s, a French inventor by the name of Georges Jean Marie Darrieus designed a vertical-axis wind turbine that has been referred to as the ‘Darrieus design’ or ‘eggbeater’. The Darrieus design uses a series of sails that are fixed at a set angle and arranged symmetrically around a vertical axis. The symmetry of the sails provides a very effective means of generating a rotational force to the vertical shaft axis. These types of vertical-axis wind turbines are used today on tall buildings to utilise the high wind velocity found at higher altitudes. Unfortunately, sail fatigue, which causes premature failure of the system, is a common problem associated with the Darrieus design.

As an alternative to the Darrieus design, the US Patent No. 4,449,053, issued to Kutcher, shows a vertical-axis wind turbine that uses vertically positioned rotor blades. Blades are connected both at the top and bottom of a vertically extending rotor tube. While the Kutcher design reduces sail fatigue, the vertically positioned rotor blades do not easily capture wind at all angles, thereby reducing their effectiveness.

Other Vertical-Axis Designs

Another variation is the Giromill Cycloturbine, shown in US Patent No. 7,315,093, issued to Graham. The Giromill Cycloturbine has sails mounted such that the sails can rotate around an axis. The design of the Cycloturbine allows the sails to be pitched such that the sails are always at an angle relative to the wind. A main advantage to this design is that the torque generated remains almost constant over a fairly wide angle. Therefore, a Cycloturbine with three or four sails has a fairly constant torque. Predetermining the range of angles, the torque approaches a possible maximum torque, wherein the system generates more power. The system also has the advantage of being able to self start by pitching the down-wind moving sails flat to the wind to generate drag and start the turbine spinning at a low speed. One drawback to this design is that the sail pitching mechanism is complex and generally heavy, and a wind direction sensor must be added to the design in order to properly pitch the sails.

Current Designs

Currently, the commercial application of wind energy harnessing is primarily, if not exclusively, horizontal-axis wind turbines, even though vertical-axis wind turbines avoid most of the disadvantages inherent in the horizontal-axis design. For example, vertical-axis wind turbines are omni-directional and have a lower cut-in wind speed and higher cut-out speed, thus making the window of operation wider. Also, vertical-axis wind turbines can have components that need servicing located at the bottom end of the structure making access more convenient. Vertical-axis wind turbines also allow for lower-ratio gearboxes, which are less expensive and more efficient than the gearboxes needed to operate horizontal-axis wind turbines, Further, vertical-axis wind turbines are able to operate at a higher wind speed and at lower risk of suffering wind damage. Finally, vertical-axis wind turbines are more suited to a simpler design and construction.

Thus, there is a continuing need for a vertical-axis wind turbine that captures the inherent advantages of the vertical-axis design, yet improves upon the drawbacks of existing vertical-axis designs.

Summary of Findings

The conclusion that was drawn from studying previous designs in this field was that an improved version, without the drawbacks of the previous models, could be created by using reinforced square rigged sails fixed at a 90 degree angle, at the tip of parallel and horizontal yardarms. Such a design is described below.

Square Rigged Sail Wind Turbine

The suggested new wind turbine is a vertical axis turbine designed to generate electricity at both onshore and offshore locations. The turbine is driven by a square rigged sail conformation that can include one or more stacked sail assemblies. Each sail assembly includes a main shaft having a vertical axis of rotation, with each successive sail assembly in the stack sharing the main shaft. Each sail assembly includes one or more yardarms that extend horizontally from the main shaft. The sails are attached to the yardarms such that the main shaft is central and positioned between the sails.

From the top down in the blue diagram (figure 1), the second and fourth sail assemblies are obscured showing two sails only for each. Also, the entire rear vertical column, the vertical main shaft axis, and corner bracing on the lower three sail assemblies are obscured in this diagram.

Biography of the Author

Since 2007, Jon Howard has been a research specialist, for H Energy Innovations, in

southern California, USA, where extensive studies have been conducted in wind energy. Mr Howard’s research on wind energy development and studies in meteorology and the environment has led him to create a vertical-axis wind turbine with greater utility advantage than the previous designs.{/access}

- Category: Articles

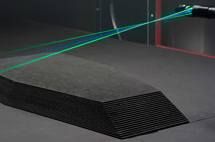

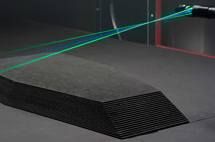

On Proper Physical Modelling of Atmospheric Boundary Layer Flow over Hills

One of today’s hot topics in energy policy and its economics is the reduction of uncertainties in wind resource assessment and forecasting. This article provides details of the state of the art for wind tunnel modelling for atmospheric flow over topography. Such physical modelling can be helpful in various ways. At present, numerical tools for wind energy assessment usually fail in complex terrain. Additionally, most numerical models cannot take wind gusts into account because of computational limits. So-called turbulent fluctuations of atmospheric wind speed are currently the focus of a lot of wind energy research. Better understanding of wind turbulence will help to reduce wind turbine damage and will improve wind energy production. Wind tunnel flows are able to depict turbulence effects if they are set up carefully, and are also able to test numerical models. To summarise, wind tunnel measurements can serve as a method of validating numerical models and thereby predicting data with both high spatial and time resolution.

One of today’s hot topics in energy policy and its economics is the reduction of uncertainties in wind resource assessment and forecasting. This article provides details of the state of the art for wind tunnel modelling for atmospheric flow over topography. Such physical modelling can be helpful in various ways. At present, numerical tools for wind energy assessment usually fail in complex terrain. Additionally, most numerical models cannot take wind gusts into account because of computational limits. So-called turbulent fluctuations of atmospheric wind speed are currently the focus of a lot of wind energy research. Better understanding of wind turbulence will help to reduce wind turbine damage and will improve wind energy production. Wind tunnel flows are able to depict turbulence effects if they are set up carefully, and are also able to test numerical models. To summarise, wind tunnel measurements can serve as a method of validating numerical models and thereby predicting data with both high spatial and time resolution.

By Graciana Petersen, Bernd Leitl and Michael Schatzmann, EWTL Environmental Wind Tunnel Laboratory, Germany

One of today’s hot topics in energy policy and its economics is the reduction of uncertainties in wind resource assessment and forecasting. This article provides details of the state of the art for wind tunnel modelling for atmospheric flow over topography. Such physical modelling can be helpful in various ways. At present, numerical tools for wind energy assessment usually fail in complex terrain. Additionally, most numerical models cannot take wind gusts into account because of computational limits. So-called turbulent fluctuations of atmospheric wind speed are currently the focus of a lot of wind energy research. Better understanding of wind turbulence will help to reduce wind turbine damage and will improve wind energy production. Wind tunnel flows are able to depict turbulence effects if they are set up carefully, and are also able to test numerical models. To summarise, wind tunnel measurements can serve as a method of validating numerical models and thereby predicting data with both high spatial and time resolution.

One of today’s hot topics in energy policy and its economics is the reduction of uncertainties in wind resource assessment and forecasting. This article provides details of the state of the art for wind tunnel modelling for atmospheric flow over topography. Such physical modelling can be helpful in various ways. At present, numerical tools for wind energy assessment usually fail in complex terrain. Additionally, most numerical models cannot take wind gusts into account because of computational limits. So-called turbulent fluctuations of atmospheric wind speed are currently the focus of a lot of wind energy research. Better understanding of wind turbulence will help to reduce wind turbine damage and will improve wind energy production. Wind tunnel flows are able to depict turbulence effects if they are set up carefully, and are also able to test numerical models. To summarise, wind tunnel measurements can serve as a method of validating numerical models and thereby predicting data with both high spatial and time resolution.By Graciana Petersen, Bernd Leitl and Michael Schatzmann, EWTL Environmental Wind Tunnel Laboratory, Germany

- Category: Articles

A Study of the Estimation of Wind Speeds in Wind Farms

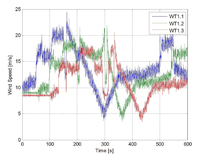

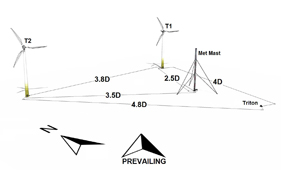

Recent work on the optimisation and control of wind farms has mostly been based on wind speed and direction. Generally this has involved using a number of additional sensors (e.g. anemometers, aerometers or lidars). However, in the study reported here, kk-electronic a/s used existing measurements from its control and data acquisition systems in the wind turbines and wind farm to estimate the wind speed and direction in the different parts of the wind farm.

Recent work on the optimisation and control of wind farms has mostly been based on wind speed and direction. Generally this has involved using a number of additional sensors (e.g. anemometers, aerometers or lidars). However, in the study reported here, kk-electronic a/s used existing measurements from its control and data acquisition systems in the wind turbines and wind farm to estimate the wind speed and direction in the different parts of the wind farm.

By Peter Fogh Odgaard, kk-electronic a/s, Denmark

Recent work on the optimisation and control of wind farms has mostly been based on wind speed and direction. Generally this has involved using a number of additional sensors (e.g. anemometers, aerometers or lidars). However, in the study reported here, kk-electronic a/s used existing measurements from its control and data acquisition systems in the wind turbines and wind farm to estimate the wind speed and direction in the different parts of the wind farm.

Recent work on the optimisation and control of wind farms has mostly been based on wind speed and direction. Generally this has involved using a number of additional sensors (e.g. anemometers, aerometers or lidars). However, in the study reported here, kk-electronic a/s used existing measurements from its control and data acquisition systems in the wind turbines and wind farm to estimate the wind speed and direction in the different parts of the wind farm.By Peter Fogh Odgaard, kk-electronic a/s, Denmark

- Category: Articles

Sodar-Based Wind Sensors have a Role in Power Curve Calculations

As remote sensing systems like sodar and lidar become more widely used in the wind energy industry, their value in applications throughout the wind information life cycle becomes more apparent. Among those applications with the greatest potential is power curve measurement.

As remote sensing systems like sodar and lidar become more widely used in the wind energy industry, their value in applications throughout the wind information life cycle becomes more apparent. Among those applications with the greatest potential is power curve measurement.

By Niels LaWhite, Chief Scientist, Second Wind, USA

As remote sensing systems like sodar and lidar become more widely used in the wind energy industry, their value in applications throughout the wind information life cycle becomes more apparent. Among those applications with the greatest potential is power curve measurement.

As remote sensing systems like sodar and lidar become more widely used in the wind energy industry, their value in applications throughout the wind information life cycle becomes more apparent. Among those applications with the greatest potential is power curve measurement.By Niels LaWhite, Chief Scientist, Second Wind, USA

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.