- Category: Articles

Remember: All Rock is Not the Same

Wind turbine generators are a major investment in a wind energy project. Costs may be as high as US$ 1.5 million per turbine. It is, therefore, critical to protect that investment by conducting a thorough geotechnical investigation of each foundation pad upon which the wind turbine generators will be founded.

Wind turbine generators are a major investment in a wind energy project. Costs may be as high as US$ 1.5 million per turbine. It is, therefore, critical to protect that investment by conducting a thorough geotechnical investigation of each foundation pad upon which the wind turbine generators will be founded.

By William Gates, Principal Geological Engineer, Kleinfelder, Inc., USA .

Wind turbine generators are a major investment in a wind energy project. Costs may be as high as US$ 1.5 million per turbine. It is, therefore, critical to protect that investment by conducting a thorough geotechnical investigation of each foundation pad upon which the wind turbine generators will be founded.

Wind turbine generators are a major investment in a wind energy project. Costs may be as high as US$ 1.5 million per turbine. It is, therefore, critical to protect that investment by conducting a thorough geotechnical investigation of each foundation pad upon which the wind turbine generators will be founded.By William Gates, Principal Geological Engineer, Kleinfelder, Inc., USA .

- Category: Articles

A Case Study of the Houston Discovery Tower

The designers of tall buildings are showing an increasing interest in reducing the environmental impact of the construction and operation of their buildings. One of the approaches that is being used, and investigated more frequently, is the incorporation of on-site power generation, primarily by including solar and wind devices in the design of the building. One such example is the Discovery Tower, which is currently under construction in Houston, Texas. This article examines considerations for introducing wind power generation on tall buildings and how they can be specifically applied to the Discovery Tower.

The designers of tall buildings are showing an increasing interest in reducing the environmental impact of the construction and operation of their buildings. One of the approaches that is being used, and investigated more frequently, is the incorporation of on-site power generation, primarily by including solar and wind devices in the design of the building. One such example is the Discovery Tower, which is currently under construction in Houston, Texas. This article examines considerations for introducing wind power generation on tall buildings and how they can be specifically applied to the Discovery Tower.

By Brad C. Cochran, Sr Associate and Rick R. Damiani, Sr Engineer, CPP Wind Engineering, USA .

The designers of tall buildings are showing an increasing interest in reducing the environmental impact of the construction and operation of their buildings. One of the approaches that is being used, and investigated more frequently, is the incorporation of on-site power generation, primarily by including solar and wind devices in the design of the building. One such example is the Discovery Tower, which is currently under construction in Houston, Texas. This article examines considerations for introducing wind power generation on tall buildings and how they can be specifically applied to the Discovery Tower.

The designers of tall buildings are showing an increasing interest in reducing the environmental impact of the construction and operation of their buildings. One of the approaches that is being used, and investigated more frequently, is the incorporation of on-site power generation, primarily by including solar and wind devices in the design of the building. One such example is the Discovery Tower, which is currently under construction in Houston, Texas. This article examines considerations for introducing wind power generation on tall buildings and how they can be specifically applied to the Discovery Tower.By Brad C. Cochran, Sr Associate and Rick R. Damiani, Sr Engineer, CPP Wind Engineering, USA .

- Category: Articles

Historical Data and Modern Wind Assessment

The met mast lives on – for many years to come. The technology, know-how and accumulated experience in wind assessment have improved significantly in recent years, and indicate a strong future for quality sensors and higher met masts.

The met mast lives on – for many years to come. The technology, know-how and accumulated experience in wind assessment have improved significantly in recent years, and indicate a strong future for quality sensors and higher met masts.

By Tirso Vazquez, CEO, and Peter Andreas Møller, Export Manager, Kintech Engineering, Spain .

The met mast lives on – for many years to come. The technology, know-how and accumulated experience in wind assessment have improved significantly in recent years, and indicate a strong future for quality sensors and higher met masts.

The met mast lives on – for many years to come. The technology, know-how and accumulated experience in wind assessment have improved significantly in recent years, and indicate a strong future for quality sensors and higher met masts.By Tirso Vazquez, CEO, and Peter Andreas Møller, Export Manager, Kintech Engineering, Spain .

- Category: Articles

Grid Code Compliance with DFIG in Wind Power Plants without Crowbar Activation

As renewable energy production from onshore and offshore wind parks increases, and the proportion of all power generated by such decentralised systems becomes more important, grid code compliance becomes vital. There is a need for grid code requirements that define the behaviour of wind park power characteristics in the event of a grid failure at the point of common coupling with the grid. While various technical solutions exist for wind turbine power generation, the doubly fed induction generator (DFIG) technology is the preferred solution and has the biggest market share.

By Holger Gehl, Product?Line Manager, Woodward SEG, Germany .

As renewable energy production from onshore and offshore wind parks increases, and the proportion of all power generated by such decentralised systems becomes more important, grid code compliance becomes vital. There is a need for grid code requirements that define the behaviour of wind park power characteristics in the event of a grid failure at the point of common coupling with the grid. While various technical solutions exist for wind turbine power generation, the doubly fed induction generator (DFIG) technology is the preferred solution and has the biggest market share.

By Holger Gehl, Product?Line Manager, Woodward SEG, Germany .

- Category: Articles

Ready for 200-metre Met Towers ... of Light?

When Laurent and Alexandre Sauvage decided to create Leosphere in 2004 few people anticipated that lidar (light detection and ranging) remote sensing systems would become so useful to the wind-power industry in such a short time. Leosphere and its scientific partner ONERA (the French Aerospace Agency) felt that by turning these complex laser sensors into lightweight, turnkey instruments they could make this innovative technology much more accessible and relevant to industry. The Sauvage brothers realised that although the atmosphere hosted major hazards for the environment (industrial pollution, greenhouse gases) it also potentially contained a partial solution: wind power. The two brothers believed that a technology that could detect invisible atmospheric parameters a large distance away would not only be a real asset to pollution monitoring but could also be a real help to the rapidly developing wind power industry. Thus, the company decided to allocate 100% of the energies of its atmospheric scientists and opto-electronics engineers to the design of several lidars to address the specific needs of air pollution and meteorology agencies, as well as wind power companies.

When Laurent and Alexandre Sauvage decided to create Leosphere in 2004 few people anticipated that lidar (light detection and ranging) remote sensing systems would become so useful to the wind-power industry in such a short time. Leosphere and its scientific partner ONERA (the French Aerospace Agency) felt that by turning these complex laser sensors into lightweight, turnkey instruments they could make this innovative technology much more accessible and relevant to industry. The Sauvage brothers realised that although the atmosphere hosted major hazards for the environment (industrial pollution, greenhouse gases) it also potentially contained a partial solution: wind power. The two brothers believed that a technology that could detect invisible atmospheric parameters a large distance away would not only be a real asset to pollution monitoring but could also be a real help to the rapidly developing wind power industry. Thus, the company decided to allocate 100% of the energies of its atmospheric scientists and opto-electronics engineers to the design of several lidars to address the specific needs of air pollution and meteorology agencies, as well as wind power companies.By Laurent Sauvage, co-founder and scientific director, Leosphere, France

.

- Category: Articles

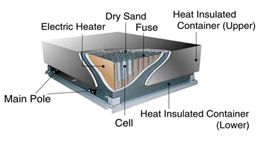

Xcel Energy Tests Battery for Storing Wind Energy

As one of the USA's leading wind power providers, Xcel Energy wants to harness renewable energy to the greatest extent possible. With that focus, the utility has launched a ground-breaking project to test cutting-edge technology for storing wind energy in batteries. Integrating variable wind and solar power production with the needs of the grid is an ongoing challenge for the utility industry. However, with a means of storing the electricity produced by those resources, that issue could go away. Xcel Energy is testing a 1 megawatt battery-storage technology, to demonstrate its ability to effectively store wind energy and move it to the grid when needed. The project marks the first use of direct wind energy storage technology in the USA.

As one of the USA's leading wind power providers, Xcel Energy wants to harness renewable energy to the greatest extent possible. With that focus, the utility has launched a ground-breaking project to test cutting-edge technology for storing wind energy in batteries. Integrating variable wind and solar power production with the needs of the grid is an ongoing challenge for the utility industry. However, with a means of storing the electricity produced by those resources, that issue could go away. Xcel Energy is testing a 1 megawatt battery-storage technology, to demonstrate its ability to effectively store wind energy and move it to the grid when needed. The project marks the first use of direct wind energy storage technology in the USA.By Sandy K. Simon, Director of Utility Innovations and Smart Grid Strategy for Xcel Energy, USA

.

- Category: Articles

Efficient Switching and Protecting

The shortage of fossil fuel resources means that the generation of electric power from wind is nowadays more necessary than ever before. For more than ten years, Woodward SEG from Kempen on the Lower Rhine has been a constant presence for those in the market for frequency inverters for wind turbine generators (WTG). Experience gained in power distribution and closed loop control engineering over this time has been fed continuously into the development of new products and technologies. State-of-the-art frequency inverters for wind turbine generators must meet the most stringent requirements with regard to switching frequencies and suitability for a wide range of supply grids. An optimised switchgear combination based on Moeller products was therefore developed for the new Concycle Wind frequency inverter generation.

The shortage of fossil fuel resources means that the generation of electric power from wind is nowadays more necessary than ever before. For more than ten years, Woodward SEG from Kempen on the Lower Rhine has been a constant presence for those in the market for frequency inverters for wind turbine generators (WTG). Experience gained in power distribution and closed loop control engineering over this time has been fed continuously into the development of new products and technologies. State-of-the-art frequency inverters for wind turbine generators must meet the most stringent requirements with regard to switching frequencies and suitability for a wide range of supply grids. An optimised switchgear combination based on Moeller products was therefore developed for the new Concycle Wind frequency inverter generation.By Dipl.-Ing. Thierry Rosant, Key Account Manager renewable energy and international OEM, Moeller GmbH, Germany

.

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.