- Details

- Category: Articles

New Approaches Enhance Gearbox Durability and Operational Efficiency

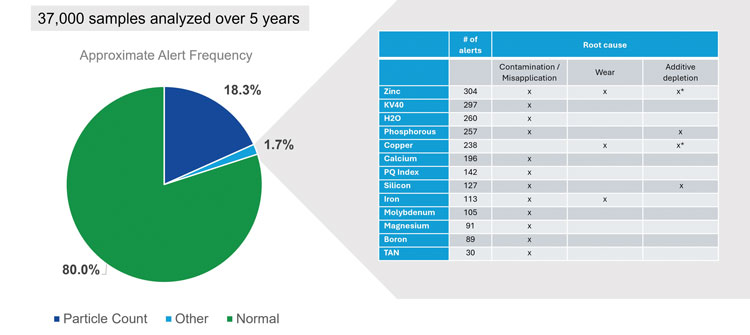

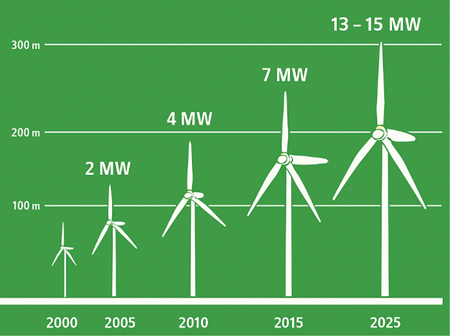

Like any modern industrial sector, the success of the wind energy industry depends on continuous innovation across its component suppliers. As turbines grow larger and more powerful, rapid technological advancement throughout the supply chain is essential to balance efficiency, reliability and cost-effectiveness. A critical, but often overlooked, area of innovation lies in lubrication, which is key to reducing friction, protecting components, and lowering maintenance costs and downtime.

By Michael L. Blumenfeld, ExxonMobil Technology and Engineering Company, USA

- Details

- Category: Articles

Incorporating Exposure, Surface Roughness, and Elevation

Incorporating Exposure, Surface Roughness, and Elevation

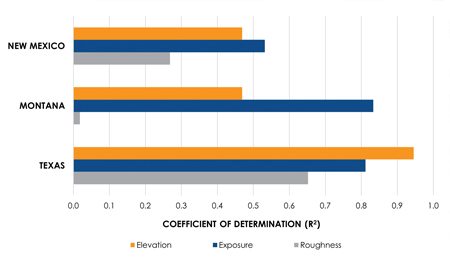

In wind resource assessment, the conventional approach to meteorological (met) mast siting has emphasised distance, recommending maintaining a maximum separation distance between each met site and the proposed wind turbine locations. This industry-accepted method assumes that shorter distances translate to better representativeness. But is distance truly the metric that matters most?

By Liz Walls and Erin Roekle, One Power Company, USA

- Details

- Category: Articles

Addressing Uncertainty Through Techno-Economic Modelling

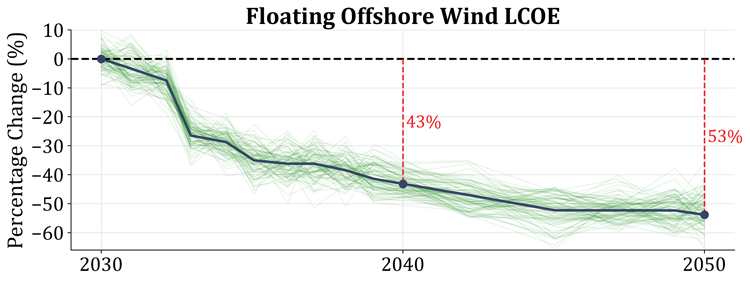

Floating offshore wind must continue to reduce costs while managing significant uncertainties, especially in heavy maintenance. Gaining real-world operational experience is crucial to close knowledge gaps and enhance maintenance strategies. At the same time, techno-economic models provide powerful tools for simulating scenarios and supporting informed decision-making. In this context, this article explores heavy maintenance challenges and presents a practical example demonstrating how these models can effectively address uncertainty in floating offshore wind projects.

By Manu Centeno-Telleria, Researcher and Lecturer, Mondragon University, Spain

- Details

- Category: Articles

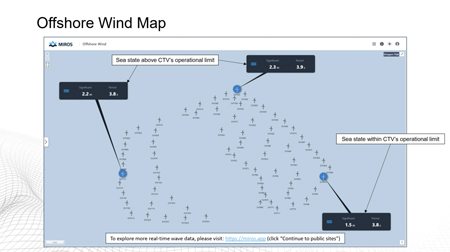

Integrating AI and Metocean Data in Offshore Operational Planning

As offshore energy operations expand into deeper, more volatile waters, accurate and timely weather forecasting becomes increasingly vital. Traditional forecasting tools, while useful, often lack the resolution and immediacy required for local, dynamic decision-making. By integrating real-time metocean measurements with artificial-intelligence-powered forecasting systems, operators can gain sharper, site-specific insight to optimise offshore operations. This article explores how these technologies are being deployed, particularly at sites such as the DanTysk wind farm, to improve weather window reliability, increase operational efficiency, and enhance crew safety, offering a glimpse of what future-ready forecasting looks like in the offshore energy industry.

As offshore energy operations expand into deeper, more volatile waters, accurate and timely weather forecasting becomes increasingly vital. Traditional forecasting tools, while useful, often lack the resolution and immediacy required for local, dynamic decision-making. By integrating real-time metocean measurements with artificial-intelligence-powered forecasting systems, operators can gain sharper, site-specific insight to optimise offshore operations. This article explores how these technologies are being deployed, particularly at sites such as the DanTysk wind farm, to improve weather window reliability, increase operational efficiency, and enhance crew safety, offering a glimpse of what future-ready forecasting looks like in the offshore energy industry.

By Richard Chen, Customer Success Manager, Miros, Norway

- Details

- Category: Articles

Preliminary Measurements and Research Agenda

As part of an ongoing research project, we conducted preliminary infrasound measurements at several Swedish wind farms. The objective was to evaluate variations in the infrasound signal between wind turbine operational and shutdown modes and to identify differences between infrasound levels measured near wind farms and at reference locations unaffected by wind turbine emissions. This article summarises early observations, outlines the analytical approach, and presents a research agenda for future work.

As part of an ongoing research project, we conducted preliminary infrasound measurements at several Swedish wind farms. The objective was to evaluate variations in the infrasound signal between wind turbine operational and shutdown modes and to identify differences between infrasound levels measured near wind farms and at reference locations unaffected by wind turbine emissions. This article summarises early observations, outlines the analytical approach, and presents a research agenda for future work.

By Per Ängskog, Kourosh Tatar and José Chilo, University of Gävle, Sweden

- Details

- Category: Articles

Enhancing Wind Farm Efficiency

Enhancing Wind Farm Efficiency

Wind farms aim to maximise energy production while maintaining safety and reliability. However, even identical turbines within the same wind farm often show significant performance gaps because of location-specific wind conditions, such as terrain variations or wake effects. Underperforming turbines, despite high availability, pose a challenge for operators seeking to optimise output. Traditional solutions, such as relocating turbines, over-rating, or adding vortex generators, often prove impractical or yield limited gains. Blade tip extensions offer a compelling alternative, increasing the rotor swept area to capture more wind and boost annual energy production by 5% to 15%. This article explores the technical basis, real-world applications, and economic benefits of blade tip extensions, highlighting their role in enhancing wind farm efficiency. By examining feasibility, challenges and industry trends, we provide practical insights for operators looking to improve underperforming turbines without major overhauls, supporting both economic and environmental goals in wind energy.

By Jack Wallace, Principal / Business Development Manager, Renewable Performance Engineering, USA

- Details

- Category: Articles

Leveraging Seasonal Predictions to Anticipate Wind Energy Returns

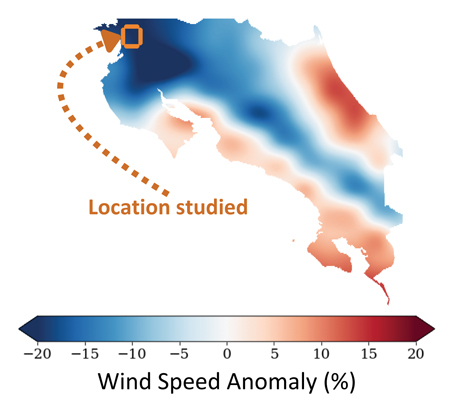

Leveraging Seasonal Predictions to Anticipate Wind Energy Returns

Seasonal production forecasts are emerging as a helpful tool to anticipate wind energy fluctuations and improve planning. Our case study on Costa Rica’s 2024 wind drought illustrates how these forecasts can be turned into actionable insights, anticipating reduced power generation months in advance. Through the use of machine learning for model post-processing and the generation of confidence intervals, the forecast accurately predicted the significant wind production drop in the region six months ahead while providing a reliable measure of uncertainty. Ultimately, these results offer a realistic example of how long-range forecasting might benefit planning and resilience in wind energy operations.

By Yazmina Zurita Martel, R&D Data Scientist, Nebbo Weather, Spain