- Details

- Category: Articles

High-Altitude Modular Post-Tensioned Concrete Wind Towers

High-Altitude Modular Post-Tensioned Concrete Wind Towers

In the race for efficiency and innovation, the wind energy sector is rethinking the very shape and logistics that define its towering giants. The industry has focused on the circular shape for towers because of its low aerodynamic drag coefficient. What if, thinking outside the box, this shape were dropped from the overall design and a new approach similar to buildings was accessed? Imagine wind towers that rival the height of city landmarks, harnessing greater wind capacities while revolutionising transportation logistics. Could these giants be modular, swiftly transported like ubiquitous shipping containers, seamlessly moving across road, rail, oceans and even the skies? The challenge extends beyond mere height – it is about speed and scalability. Can wind towers be prefabricated in factories and assembled with automotive efficiency? These questions push boundaries, urging us to shatter conventional paradigms while leveraging the very strengths of standardised container logistics.

By Andrés de Antonio, Aeventor, USA

- Details

- Category: Articles

What Is the Industry Willing to Accept to Confront It?

Floating lidar systems have revolutionised the offshore wind industry by enabling the bankability of projects at a fraction of the original cost – successful wind resource assessment campaigns are essential for the economic viability of the wind farm development process. However, one parameter measured in such campaigns – turbulence intensity – is at the centre of debate. Its accuracy, with respect to the traditional definition, is known for not reaching industry standard levels, representing a serious problem because of the lack of consensus within the industry on how to address and solve this matter. The complexity of this phenomenon means that there is no optimal solution. Several suboptimal alternatives are currently under development, but there is not yet a clear picture of which is the right option. However, this might be about to change.

Floating lidar systems have revolutionised the offshore wind industry by enabling the bankability of projects at a fraction of the original cost – successful wind resource assessment campaigns are essential for the economic viability of the wind farm development process. However, one parameter measured in such campaigns – turbulence intensity – is at the centre of debate. Its accuracy, with respect to the traditional definition, is known for not reaching industry standard levels, representing a serious problem because of the lack of consensus within the industry on how to address and solve this matter. The complexity of this phenomenon means that there is no optimal solution. Several suboptimal alternatives are currently under development, but there is not yet a clear picture of which is the right option. However, this might be about to change.

By Adrià Miquel and Giacomo Rapisardi, Eolos Floating Lidar Solutions, Spain

- Details

- Category: Articles

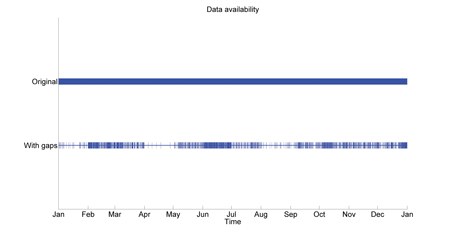

Data Availability Impacts Uncertainty of Long-Term Corrected Wind Surprisingly Little

According to common guidelines for the evaluation of site-specific wind conditions, a measurement campaign should have at least 90% data availability during a consecutive 12-month period in order to be complete. However, obtaining this high data availability with a Doppler lidar can be a challenge in locations with small amounts of atmospheric aerosols, for example in the Nordic countries or mountainous regions. Regardless of the lower data availability, the data measured in these locations can still hold valuable information that can be used to reduce uncertainties in a wind resource assessment. Therefore, we suggest that instead of discarding data with less than 90% data availability, the uncertainties due to the lower lidar data availability should be quantified and considered in the wind resource assessment. This is in line with the upcoming IEC framework for the assessment and reporting of the wind resource and energy yield.

By Pyry Pentikäinen, Adviser, Kjeller Vindteknikk, Finland

- Details

- Category: Articles

Windborne to Identify Yaw Misalignments Across a Large Fleet of Wind Turbines

According to a technical report by the National Renewable Energy Laboratory (referring to the multi-year Wind Plant Performance Prediction project), modern wind power plants in the United States were underperforming in their expected annual energy output by 3.5%–4.5%.’ [1] There are many potential causes of wind turbine underperformance. Among these are forms of underperformance caused by rotor-disrupted and/or poorly calibrated nacelle-based wind sensors that in turn feed inaccurate wind data to core wind turbine systems.

According to a technical report by the National Renewable Energy Laboratory (referring to the multi-year Wind Plant Performance Prediction project), modern wind power plants in the United States were underperforming in their expected annual energy output by 3.5%–4.5%.’ [1] There are many potential causes of wind turbine underperformance. Among these are forms of underperformance caused by rotor-disrupted and/or poorly calibrated nacelle-based wind sensors that in turn feed inaccurate wind data to core wind turbine systems.

By Itay Mor, Boaz Peled, Alex Alpert, and Guy Yakir at First Airborne, Israel

- Details

- Category: Articles

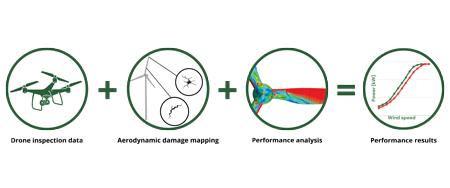

Using Drone Data to Calculate Blade Erosion AEP Loss

It is well-known that blade surface degradation, especially leading-edge erosion, leads to increased risk for turbine operators. The operational risk consists of structural and aerodynamic components, and both should be considered when planning the most effective site-specific operations and maintenance strategy.

By Nicholas Gaudern, Chief Technology Officer, PowerCurve, Denmark