CNC Onsite (Denmark) has developed a flange facing solution that meets stringent tolerances for large offshore flanges used in monopiles and transition pieces. This process ensures an optimal contact surface in flange connections for CS WIND Offshore’s customers, achieving a global flatness tolerance of one millimetre.

CNC Onsite (Denmark) has developed a flange facing solution that meets stringent tolerances for large offshore flanges used in monopiles and transition pieces. This process ensures an optimal contact surface in flange connections for CS WIND Offshore’s customers, achieving a global flatness tolerance of one millimetre.

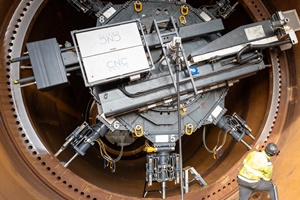

Two years ago, CS WIND Offshore contracted CNC Onsite to build a precision machine for milling large diameter flanges of transition pieces at its facility in Aalborg, Denmark. The machine, named “Goliath,” was developed and built at CNC Onsite’s headquarters in Velje, Denmark, and is used to mill flanges after the welding process.

CS WIND Offshore produces transition pieces at its 450,000 square metre facility in Aalborg and ships large diameter flanges to offshore wind farms worldwide.

Large flanges in wind turbine structures are complex to mount and require precise matching surfaces for reliable fixation. If a welded flange surface is skewed by one to two millimetres, CNC Onsite’s machine will mill the flanges to restore the optimal structural fit. The Goliath machine achieves global flatness tolerances of one millimetre and local flatness tolerances of 0.3 millimetres for an eight-metre flange.