Stratasys has announced that Gulf Wind Technology is using its additive manufacturing solutions to enhance wind turbine model testing and improvement. By adopting Stratasys Neo stereolithography (SLA) technology, Gulf Wind Technology is able to reduce the design and fabrication cycle for wind tunnel models.

Stratasys has announced that Gulf Wind Technology is using its additive manufacturing solutions to enhance wind turbine model testing and improvement. By adopting Stratasys Neo stereolithography (SLA) technology, Gulf Wind Technology is able to reduce the design and fabrication cycle for wind tunnel models.

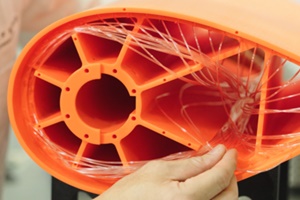

What previously took 30 to 40 days can now be completed in 3 to 4 days. The technology also allows for specialised features, such as pressure taps for real-time airflow data, which are challenging to execute with conventional manufacturing methods. Using Stratasys Neo SLA technology and Somos PerFORM Reflect material, Gulf Wind Technology can produce high-strength, stiff, and temperature-resistant models. This capability supports their rotor design process and allows for efficient post-processing and wind tunnel testing.