As of the end of June 2017, digital services in wind energy had seen deployment to over 55GW of assets, but to less than 1GW of offshore wind. The majority of the features and capabilities which can be delivered via a software-as-a-service (SaaS) model, or otherwise leverage data analytics and internet of things (IoT) systems, are likely to be agnostic to both onshore and offshore wind. Nevertheless, the potential impact on O&M cost as well as energy output optimisation will have specific implications in an offshore wind market segment.

As of the end of June 2017, digital services in wind energy had seen deployment to over 55GW of assets, but to less than 1GW of offshore wind. The majority of the features and capabilities which can be delivered via a software-as-a-service (SaaS) model, or otherwise leverage data analytics and internet of things (IoT) systems, are likely to be agnostic to both onshore and offshore wind. Nevertheless, the potential impact on O&M cost as well as energy output optimisation will have specific implications in an offshore wind market segment.

By Philip Totaro, CEO, IntelStor, LLC

While many offshore-specific capabilities are known from previous discussion in news and research publications and at industry events, they remain largely in the earlier stages of technology development and maturity.

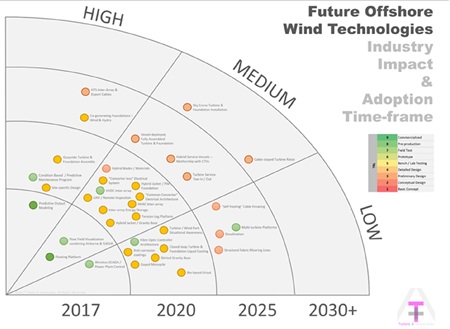

Our previous analysis of the technology trends in offshore wind reveals that while many of the near-term technologies are related to installation methods and particularly foundation technology, more commercial benefit is garnered from the early detection and mitigation of major correctives along with additional annual energy production (AEP) through advanced controls.

Specifically, digitally delivered service features which have been cultivated for onshore applications that are also directly applicable to offshore include:

1. Component damage accumulation monitoring including ‘real-time’ stress accumulation monitoring of critical drive-train, blade and electrical system components. In this case, stress can be vibratory wear or thermal cycle induced, and can be assessed through SCADA and condition monitoring system data processing techniques and/or the application of additional sensors.

2. Using damage accumulation data fed into models of the turbine control and wind farm control system to predict:

a. Component life consumption – the percentage of the effective lifetime of a component consumed to date based on wear rate/cumulative damage.

b. Component life consumption rate – the rate of change of the percentage of the effective lifetime of a component based on the manner in which the system, of which the component is a part, is operated.

c. Remaining useful component life – predicted failure time-frame based on component life consumption and component life consumption rate. Damage accumulation data must be processed and input into component life estimation models which will take into account monitored component data, software simulations, historical data analysis, wind park site conditions and neighbouring turbine data.

3. An ‘early warning’ notification system to wind farm operators about component damage accumulation, component life consumption and remaining useful life. Additional suggestions for energy price optimisation, O&M strategy, spare parts sourcing and maintenance scheduling will be incorporated into the system.

4. Energy output optimisation:

a. Uprate for AEP increase when remaining useful component life would not cause unscheduled maintenance/downtime by uprating at times of peak market price to maximise electricity price and/or regulation of duration and level of turbine uprate to ensure component life consumption or component life consumption rate are below threshold levels (or average levels).

b. Weather modelling and demand forecasting which indicates that additional power could be delivered to the grid or energy storage system.

5. Turbine life/component life preservation: Derate for component life preservation in order to prevent unscheduled maintenance/downtime by avoidance of derating at times of peak market price to maximise electricity price and/or component stress reduction with AEP loss minimised.

6. O&M strategy/maintenance scheduling: Here it is desirable to avoid sustained turbine operations that result in unscheduled turbine maintenance. These periods of unscheduled maintenance result in unavailability of the turbines and will reduce overall asset profitability. Leveraging ‘dark data’ which is not yet digitally archived, such as boroscope pictures of an end of warranty inspection, punchlists or older handwritten asset inspection logs, will be critical in building out a historical asset performance profile (sometimes referred to as a ‘digital twin’).

Additionally, offshore-specific capabilities will include developing a coordinated response for predictive maintenance scheduling where vessel availability and service technician skill-set is included in the assessment of when to optimally plan downtime. There are companies currently developing and testing commercial solutions in Europe, but a full condition-based maintenance solution has yet to be deployed in offshore wind.

Of course, wake effect mitigation will also play an especially important role in offshore services where the wind park control system will be required to incorporate an adaptive control scheme to accommodate wake shadow during yaw. A yaw offset or power derating/uprating are potential solutions which the wind park controller could implement. Experiments are already ongoing on this technology in both Europe and China.

Digital services in offshore wind represent a significant market potential, and will continue to see development along the framework outlined above.