Any new concept in an established manufacturing process or engineering operation will be costly to implement. In most cases it requires research and development, the cost of which must be absorbed by the company behind it. If the concept sounds ‘revolutionary’, at first it might seem either difficult or impossible to achieve. On the other hand, in many industrial applications – out of necessity – research and development is a continuous endeavour to make a product more efficient, have improved performance, cheaper and so on.

Any new concept in an established manufacturing process or engineering operation will be costly to implement. In most cases it requires research and development, the cost of which must be absorbed by the company behind it. If the concept sounds ‘revolutionary’, at first it might seem either difficult or impossible to achieve. On the other hand, in many industrial applications – out of necessity – research and development is a continuous endeavour to make a product more efficient, have improved performance, cheaper and so on.By Ahmad Hemami, McGill University, Montreal, Canada

This has especially been observed in the evolution of wind turbines. The manufacturers of wind turbines are (and should be) overly cautious about new ideas that can, in the end, represent a win-or-lose situation for them. We have seen examples of this in a recent article [ref. 1].

Breaking away from an accustomed scenario is more difficult to digest. An example is currently in progress with Seawind’s two-blade design and no blade pitching (which claims to outperform all existing three-blade wind turbine designs) [ref. 2].

Although it is not evident in the beginning whether an idea/concept is worth the effort and cost, sometimes a preliminary evaluation sheds light on a go /no-go decision.

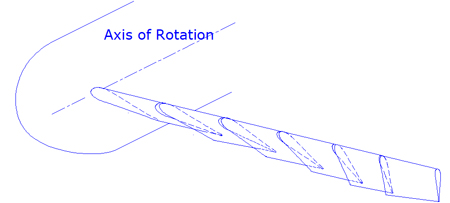

Recently there has been talk about wind turbine blades with variable (adjustable) twist angle [ref. 3]. From various viewpoints, such a capability will be very useful and beneficial to enhance the productivity of a wind turbine as well as reduce the size of certain components.

We know that the twist angle in horizontal axis wind turbines is of paramount importance. It is the first step in designing a turbine blade before mechanical strength and other parameters are brought into consideration. The twist angle, however, is not so easy to determine and must be based on optimisation of the performance or productivity of a turbine under the range of wind speeds that it experiences in operation.

The reason for the necessity of optimisation is that the blade twist magnitude can be determined for one wind/rotational speed pair. Thus, the values (along the length of a blade) for the twist angle can be calculated, for example for 8m/s wind speed and 14rpm rotor speed. The turbine power coefficient, thus, has its highest value through the appropriate twist angle for only this pair (8m/s / 14rpm) but not for other wind speeds even if it operates at a fixed speed (older turbines). With variable speed turbines the problem becomes even more involved, since there are numerous wind/rotational speed pairs to consider, which means more calculations. The final result is a compromise between many possible scenarios after adjustments and blending of airfoils when necessary.

Ideally (theoretically), adjusting a turbine twist for each wind speed would considerably increase the productivity of the turbine. The very first question is, though, whether it is practical.

There are a number of points that make this concept impractical in terms of manufacturing, operations, maintenance, aerodynamic properties and cost. If a blade is divided into a few segments, for instance an 80-metre long blade would consist of five 16-metre segments. Then for the manipulation of each segment with respect to its preceding part, a sufficiently strong shaft with its hydraulic or electrical mechanism – similar to that of the blade pitch system – is necessary. This by itself (a) adds to the blade weight, (b) makes the blade surface uneven with sharp edges, and (c) makes the whole blade mechanically weaker in the first place.

Then comes the question of the actuators to move each segment, especially if they are hydraulic. Should they be local at each joint or centralised in the hub, with a pipeline, flexible between segments, to extend along a blade? More important than how this actuator system is arranged is the question of its maintenance. Definitely with more components involved, the probability of failure and the need to repair augments. Should a repair job be performed from inside the blade or from outside?

The blade outer shell has more exposure to harsh operating conditions through its edges at each segment end, even if a protective fabric (which is absolutely necessary) is devised to cover each blade joint (the gap between segments) from dust, rain and snow, humidity, sea salt and so on. This protective cover by itself adds to the manufacturing and maintenance issues.

Blade transportation should also be pointed out, although it looks positive at first glance. But if a blade comes in a number of segments that must be assembled, does it call for on-site facilities and expertise for assembling, balancing and possibly testing for performance before erection?

Considering all these concerns together, the concept of a variable twist blade can be deemed impractical.

Further Reading

- de Vries, E. 2020. 40 promising turbine designs that fell short of expectations. Windpower Monthly, October, https://www.windpowermonthly.com/article/1698148/40-promising-turbine-designs-fell-short-expectations

- The Maritime Executive. 2022. Finalizing design for two-blade semi-submersible floating wind turbine. The Maritime Executive, May, https://www.maritime-executive.com/article/finalizing-design-for-two-blade-semi-submersible-floating-wind-turbine

- Maldonado, C., Hall, J., Tierney, E. and Roetzer, J. 2022. Adaptable blades for offshore wind. Windtech International 18(1), 16–18.