Thinking about the time when a major portion of electricity will be provided by wind, solar and other renewable sources, in which power converters play a significant role, the question of power quality pops up. Presently, in many places the amount of generated energy that passes through these converters is very small but now that there is a shift from type 3 turbines (with doubly-fed induction generator, DFIG) to type 4 (direct drive) for the growing offshore turbines, the presence of harmonics lowers the quality of the generated power. In turbines equipped with a DFIG at least 2/3 of the power travels through the stator winding, i.e. there is a clean sinusoidal waveform with no harmonics, but with direct-drive turbines, inevitably all the generated electricity must pass through converters.

Thinking about the time when a major portion of electricity will be provided by wind, solar and other renewable sources, in which power converters play a significant role, the question of power quality pops up. Presently, in many places the amount of generated energy that passes through these converters is very small but now that there is a shift from type 3 turbines (with doubly-fed induction generator, DFIG) to type 4 (direct drive) for the growing offshore turbines, the presence of harmonics lowers the quality of the generated power. In turbines equipped with a DFIG at least 2/3 of the power travels through the stator winding, i.e. there is a clean sinusoidal waveform with no harmonics, but with direct-drive turbines, inevitably all the generated electricity must pass through converters.By Ahmad Hemami, McGill University, Montreal, Canada

Looking for true characteristic performance of the converters used in wind, I came across some facts about their reliability, which is often more important than their quality. For many years, more in the case of older turbines, the gearbox has been marked as the troublesome component that we need to get rid of. This reality has led to efforts and results in two directions: 1) improvements in gearbox design, manufacturing and application, and 2) the development of direct-drive turbines.

Several studies have been performed on the reliability of wind turbine components and their failure, although there are no universal criteria to define the importance/severity of any failure or to categorise various components and their subcomponents. For instance, categorisation could be based on the total cost and the lost revenue for the downtime, or it could be based on the necessary time of repair and putting a turbine back in service. In the earlier turbines the cause of failure, as the studies show, could be mechanical but not necessarily associated with moving parts and the drive-train. Examples could be the hatches not being properly closed or the sensors malfunctioning.

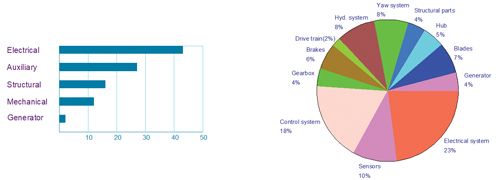

After improvements to all the simpler devices, gearbox failure became the focus, which again showed how mistakes in design, manufacturing, installation and/or bad maintenance could eventually lead to big losses (repair or complete replacement of a gearbox has both the longest downtime and the highest cost). But, again, the lessons were learned, and the manufacturers and users corrected the errors and improved the condition. Indeed, a survey of wind turbine component failure rate by Bala et al. (2012) points to the electrical system (that should contain the power converters) as the number one cause of wind turbine failure (see Figure 1, showing the percentage failure for different categories of components, with more data available in the right figure). The graphs in Figure 1 are based on a great number of turbines, rated below and above 1MW. A more recent study (Carroll et al. 2016) considering about 350 modern offshore (2 to 4MW) wind turbines and 1,768 turbine years of operation concludes that the power supply/converter has a high percentage of major repair. In this study the categorisation was based on the total cost of repair.

It is true that the climate has a significant effect on all these analyses. In other words, one cannot treat all data the same way. This is another difficulty in dealing with a study of what the cause of a specific failure is. For instance, turbines installed in regions that are subject to lightning have more blade damage. However, our concentration is only on issues with direct-drive versus geared turbines and the reliability of power converters. For a direct-drive versus geared system, we find the following statement from a comparison in 2018 by Ozturk et al.: ‘In most of the subsystems direct-drive wind turbines seemed to have a higher failure rate than geared-drive wind turbine in the same climatic region. Direct-drive technology would be thought to be an ideal design for offshore applications because of its less complexity; however this study shows opposite.’

Along the same lines, regarding the failure of insulated-gate bipolar transistor power converters, according to a detailed study, ‘The problem of high converter failure rates is limited neither to single manufacturers nor to specific sites. It is rather observed worldwide and in a multitude of different WT types …’ (Fischer et al. 2019). The report points to observing signs of the effect of humidity on the failed converter modules.

Now, considering the sea, salt and humidity, and a full power transfer of say 10MW, one doubts whether a direct-drive system is the right choice for offshore wind turbines.

Further Reading

- Bala, S., Pan, J., Das, D., Apeldoorn, O. and Ebner, S. 2012. Lowering failure rates and improving serviceability in offshore wind conversion-collection systems. IEEE Power Electronics and Machines in Wind Applications, 1–7.

- Carroll, J., McDonald, A. and McMillan, D. 2016. Failure rate, repair time and unscheduled O&M cost analysis of offshore wind turbines. Wind Energy 19, 1107–1119.

- Fischer, K. et al. 2019. Reliability of power converters in wind turbines: exploratory analysis of failure and operating data from a worldwide turbine fleet. IEEE Transactions on Power Electronics 34(7), 6332–6344.

- Ozturk, S., Fthenakis, V. and Faulstich, S. 2018. Failure modes, effects and criticality analysis for wind turbines considering climatic regions and comparing geared and direct drive wind turbines. Energies 11(9), 2317.