It is likely that many of the people who in one way or another work with wind turbines, the environment and energy know about the good, the bad and the ugly of wind turbines. The good news is that the ugly is expected to become less so.

It is likely that many of the people who in one way or another work with wind turbines, the environment and energy know about the good, the bad and the ugly of wind turbines. The good news is that the ugly is expected to become less so.By Ahmad Hemami, McGill University, Montreal, Canada

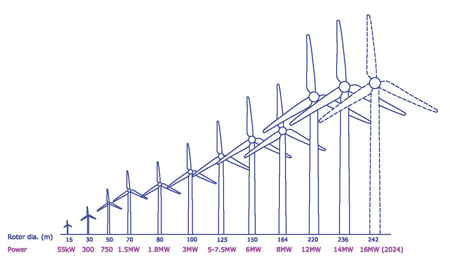

All the technological advancements during the last 40+ years undoubtedly demonstrate the results of good efforts. This progress is represented in the increased turbine size and energy capture. Figure 1 shows this growth for typical turbines. Compared with a coal-fired power plant, a 5MW turbine, for instance, reduces carbon dioxide emission to the atmosphere by 28 tons per day (about 17 tons for natural gas). That is what we need; that is the good.

However, like everything else, it is not all good. The bad side of wind turbines is their effect on the ecosystem, especially during construction, which disturbs nature and creatures living in the area. This disturbance is more noticeable for offshore turbines, which are larger, far out to sea, and for which the working conditions are harsher, leading to lengthier operations and increased disturbance of the seabed and marine life. With respect to the long-term effects, probably the offshore turbines are not worse than the onshore ones. They may kill birds, but as with onshore turbines, the numbers are much less than those killed by cats and colliding with buildings.

However, like everything else, it is not all good. The bad side of wind turbines is their effect on the ecosystem, especially during construction, which disturbs nature and creatures living in the area. This disturbance is more noticeable for offshore turbines, which are larger, far out to sea, and for which the working conditions are harsher, leading to lengthier operations and increased disturbance of the seabed and marine life. With respect to the long-term effects, probably the offshore turbines are not worse than the onshore ones. They may kill birds, but as with onshore turbines, the numbers are much less than those killed by cats and colliding with buildings.The ugly is well represented by the landfill in Figure 2. The best thing that the wind turbine manufacturers can do, and that is a real advancement, is to find solutions to this problem. I was so delighted to find out that at least three of the large manufacturers are working in this direction. Recycling is the solution. In the past, recycling was rarely considered. Everything was put into the rubbish/waste, and unfortunately there are places where this still happens. Eventually, we realised that we cannot selfishly pile up our waste on land and in the sea forever. This applies to many man-made products, including wind turbines. We cannot just continue to build more and more of something and then throw it away afterwards.

Recycling can be (initially) costly but it is the best way (if not the only way) to tackle this man-made problem. The hidden cost added to a product to take care of the rubbish and pollution should not be ignored. Only responsible companies/governments/people pay attention to it. Ignoring cleaning up is an irresponsible action.

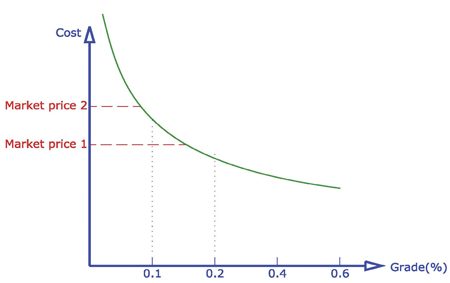

Manufacturing without considering recycling is the same as what happens in mining when ignoring (leaving behind) plenty of an orebody because it is of a lower grade and its removal involves a more costly process. This maximises the profit but ignores the long-term effects. This is shown in Figure 3. All the ore with a grade below 0.15%, for example, can be left in the abandoned mine, although there is still plenty of the mineral in the deposit.

In recycling, the recovered material can either be used for making the same item(s) or for a new application that does not require extracting the original ingredients and is less costly. The quantitative balance between the recovered substance and the new application is important. The best practice is to use the recycled material as the raw material for manufacturing the same product. Nonetheless, for wind turbine blades there are many applications that can use the lightweight crushed composite material as a filling element in a mixture.

In recycling, the recovered material can either be used for making the same item(s) or for a new application that does not require extracting the original ingredients and is less costly. The quantitative balance between the recovered substance and the new application is important. The best practice is to use the recycled material as the raw material for manufacturing the same product. Nonetheless, for wind turbine blades there are many applications that can use the lightweight crushed composite material as a filling element in a mixture.For wind turbine recycling, Vestas and Siemens Gamesa have found ways to separate the resin from the other components to make it possible to reclaim the glass, carbon fibre, wood, etc. GE, on the other hand, considers the alternative application of using crushed turbine blades for mixing with asphalt or other construction materials.

Further Reading

- Barsoe, T. 17 May 2021. End of wind power waste? Vestas unveils blade recycling technology. (https://www.reuters.com/business/sustainable-business/end-wind-power-waste-vestas-unveils-blade-recycling-technology-2021-05-17/)

- Siemens Gamesa Renewable Energy. 2021. Recyclable blade. Taking responsibility. Blade by blade. (https://www.siemensgamesa.com/en-int/-/media/siemensgamesa/downloads/en/sustainability/environment/siemens-gamesa-20210901-recycableblade-infographic-finalen.pdf)

Yang, Y. et al. 2012. Recycling of composite materials. Chemical Engineering and Processing 51, 53–68.