- Details

- Category: Articles

Development, Validation and Certification of Ingeteam’s Power Converter in Suzlon’s S11x Wind Turbine

During the last 20 years, wind power’s share in electricity generation has substantially grown, making the power quality and stability of wind systems increasingly important. Consequently, the grid codes (which establish the requirements that all generation systems must fulfil in order to be allowed to connect to the grid) have been updated in order to guarantee the stability of the grid. Until the recent past, wind turbines were allowed to disconnect from the grid when transient changes in grid voltage might jeopardise the integrity of their elements, especially the power converter. However, nowadays, this is no longer allowed. Moreover, the turbines must also support the grid with active and reactive current during these transient conditions.

By Aritz Lorea, Product Manager, Wind Business, Ingeteam Power Technology, Spain

- Details

- Category: Articles

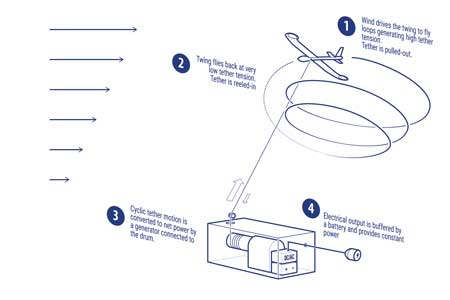

Mobile Wind Energy with Tethered Wings for Off-Grid Applications

TwingTec is currently working on new wind energy technology that has the potential to unlock so far unused wind energy resources. The concept relies on a tethered wing which flies like a kite to harness the energy of wind. This enables access to winds at higher altitudes, which are typically stronger and more constant. No tower or foundation is needed, leading to an order of magnitude mass reduction compared to conventional wind turbines. The system can be containerised allowing for easy deployment. A first prototype has been built and tested. A product concept for a 100kW mobile wind energy system has been developed which addresses the needs of the off-grid market. Long-term systems in the megawatt range could contribute significantly to the global energy market.

TwingTec is currently working on new wind energy technology that has the potential to unlock so far unused wind energy resources. The concept relies on a tethered wing which flies like a kite to harness the energy of wind. This enables access to winds at higher altitudes, which are typically stronger and more constant. No tower or foundation is needed, leading to an order of magnitude mass reduction compared to conventional wind turbines. The system can be containerised allowing for easy deployment. A first prototype has been built and tested. A product concept for a 100kW mobile wind energy system has been developed which addresses the needs of the off-grid market. Long-term systems in the megawatt range could contribute significantly to the global energy market.

By Dr Rolf Luchsinger, Co-founder & CEO, TwingTec AG, Switzerland

- Details

- Category: Articles

TYER Wind’s Wind Converter

The TYER Wind vertical axis wind converter harnesses wind power using flapping wings that perfectly mimic the motion of one of the most energy-efficient birds: the hummingbird. Invented by Anis Aouini, the technology is a radical solution inspired by nature and turns out to be efficient, eco-friendly and perfectly scalable. No rotating blades; just flapping wings that convert wind power into green electricity thanks to their revolutionary 3D Aouinian kinematics.

The TYER Wind vertical axis wind converter harnesses wind power using flapping wings that perfectly mimic the motion of one of the most energy-efficient birds: the hummingbird. Invented by Anis Aouini, the technology is a radical solution inspired by nature and turns out to be efficient, eco-friendly and perfectly scalable. No rotating blades; just flapping wings that convert wind power into green electricity thanks to their revolutionary 3D Aouinian kinematics.

By Anis Aouini, Inventor, Co-founder & Chairman of TYER Wind, Tunisia

- Details

- Category: Articles

Turbine Foundations as an Opportunity for Marine Biodiversity

In view of the negative effects wind farms may have on the environment, especially during construction, the reef and reserve effects of turbine foundations (or their capacity to host diverse marine species) are often put forward as a sign of a project’s positive long-term footprint. Taking a closer look at the underlying ecological processes, there is more than meets the eye, and the potential ecological benefits of offshore wind farms go far beyond what could simply be considered as a few fish swimming around a monopile.

In view of the negative effects wind farms may have on the environment, especially during construction, the reef and reserve effects of turbine foundations (or their capacity to host diverse marine species) are often put forward as a sign of a project’s positive long-term footprint. Taking a closer look at the underlying ecological processes, there is more than meets the eye, and the potential ecological benefits of offshore wind farms go far beyond what could simply be considered as a few fish swimming around a monopile.

By Martin Perrot and Matthieu Lapinski, Seaboost, France

- Details

- Category: Articles

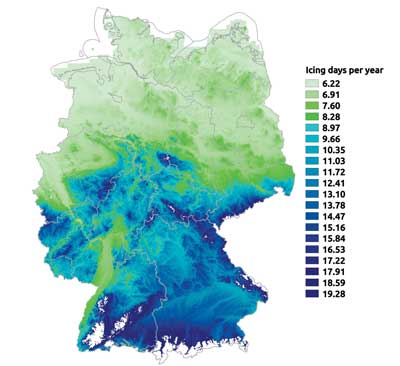

Experiences and Recent Developments in Germany

Experiences and Recent Developments in Germany

Ice throw from wind turbines is a serious environmental hazard. Experience in Germany may serve as a contribution to future standardisation of ice throw from wind turbines. No national or international standards exist, but they are urgently needed. The aim of this article is to give an overview of the critical points which should be assessed in a future guideline.

By Thomas Hahm and Nicole Stoffels, F2E Fluid & Energy Engineering, Germany

- Details

- Category: Articles

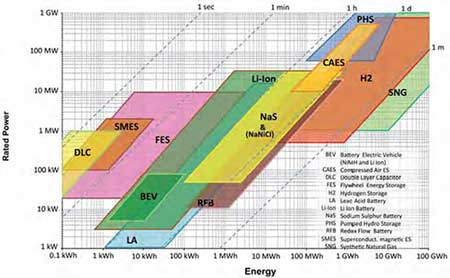

An Integrated Energy Storage System

An Integrated Energy Storage System

Wind speed is unpredictable and variable such that the power output from wind turbines often does not coincide with demands from the national grid. In the UK, constraint payments are made to wind farm owners when the turbines are shut down because of lack of demand for their power. Clearly the wind farm owner would wish to sell any energy generated whatever the demand and also be able to deliver higher power if necessary on demand. Here a novel wind–tidal integrated storage power generation system is described that addresses these issues.

By Mike Lewis, RGL Associates, UK

- Details

- Category: Articles

Using Pneumatic Power to Generate Wind Energy

Using Pneumatic Power to Generate Wind Energy

Over 60 years ago a 100kW test wind turbine was built with pneumatic power transmission in southern England (Figure 1), based on a design patented by M. Andreau. Test results from the turbine showed a lower energy extraction than was obtained by wind turbines with conventional mechanical power transmission, and therefore the pneumatic power transmission was abandoned, without attempting to improve it. Our team has re-investigated this type of transmission, and following a number of patented innovations we have been able to considerably improve on the previous results. We are now hoping to upscale our working models for field testing.

By Dr Endre Mucsy, Hungary

Below we discuss the differences between conventional and pneumatic turbine types and their resulting properties. Why was the potential of pneumatic power transmission underestimated and abandoned? What design changes did we make to improve the efficiency of the pneumatic turbine, and how have we tested them? Finally, how much energy is there in the wind and what proportion can be utilised?