- Details

- Category: Articles

Reducing Cost and Risk in Floating Offshore Wind

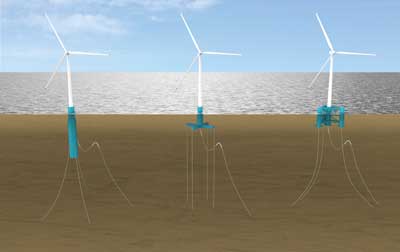

In recent years, floating wind has gradually matured as a technology, progressing from being the subject of academic research to a handful of full-scale, stand-alone prototype projects (Hywind in Scotland, Principle Power in Portugal and the FORWARD project in Japan), to the development of multiple pre-commercial arrays. Technological advances in floating wind will open up opportunities to exploit the abundant wind resource in deeper water sites where it is currently not possible to deploy fixed-bottom foundations, making this an important area of research for the offshore wind industry. This article analyses the costs and risks of the three most common types of floating wind structure and compares them to those of a fixed-bottom monopile wind farm. It also provides an outlook on the technology’s future and notes areas where further research is needed.

In recent years, floating wind has gradually matured as a technology, progressing from being the subject of academic research to a handful of full-scale, stand-alone prototype projects (Hywind in Scotland, Principle Power in Portugal and the FORWARD project in Japan), to the development of multiple pre-commercial arrays. Technological advances in floating wind will open up opportunities to exploit the abundant wind resource in deeper water sites where it is currently not possible to deploy fixed-bottom foundations, making this an important area of research for the offshore wind industry. This article analyses the costs and risks of the three most common types of floating wind structure and compares them to those of a fixed-bottom monopile wind farm. It also provides an outlook on the technology’s future and notes areas where further research is needed.

By Robert Proskovics and Gavin Smart, ORE Catapult, Glasgow, UK

- Details

- Category: Articles

Anticipating Quarterly Winds and Revenues One Month Ahead

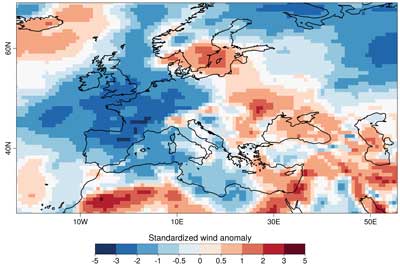

The wind power industry has traditionally used fixed climatologies for anticipating wind speed and wind generation beyond 15 days ahead. However, wind is highly variable at monthly and seasonal scales, and anomalies occur around the globe every now and then. Assuming that future conditions will be similar to average past conditions has several inherent shortcomings. Recent advances in dynamical modelling systems have opened new opportunities for seasonal prediction of wind speed that can improve current practices. Ensemble ocean–atmosphere numerical simulations can provide meaningful forecasts that indicate the probability of having above-normal, normal or below-normal wind conditions in the next season with one month of advance warning. Through an analysis of some case studies we will explore in this article how seasonal predictions of wind speed and generation have been made possible, what their quality is and how they can help in the decision-making processes for practical applications.

The wind power industry has traditionally used fixed climatologies for anticipating wind speed and wind generation beyond 15 days ahead. However, wind is highly variable at monthly and seasonal scales, and anomalies occur around the globe every now and then. Assuming that future conditions will be similar to average past conditions has several inherent shortcomings. Recent advances in dynamical modelling systems have opened new opportunities for seasonal prediction of wind speed that can improve current practices. Ensemble ocean–atmosphere numerical simulations can provide meaningful forecasts that indicate the probability of having above-normal, normal or below-normal wind conditions in the next season with one month of advance warning. Through an analysis of some case studies we will explore in this article how seasonal predictions of wind speed and generation have been made possible, what their quality is and how they can help in the decision-making processes for practical applications.

By Llorenç Lledó, Barcelona Supercomputing Center, Barcelona

- Details

- Category: Articles

A Revolutionary Concept Featuring a Ring-Shaped Generator

Members of the MegaWindForce (MWF) team developed a highly efficient variable transmission system back in 2012. While researching whether this invention would contribute to the efficiency of wind turbines they became aware of the catch 22 situation of the wind industry: rotors need to be bigger to harvest more energy, resulting in lower numbers of revolutions, which makes the design of generators more complex and relatively more expensive. A new concept was developed, where the main shaft was replaced by a ring. This revolutionary concept resulted in several patents.

Members of the MegaWindForce (MWF) team developed a highly efficient variable transmission system back in 2012. While researching whether this invention would contribute to the efficiency of wind turbines they became aware of the catch 22 situation of the wind industry: rotors need to be bigger to harvest more energy, resulting in lower numbers of revolutions, which makes the design of generators more complex and relatively more expensive. A new concept was developed, where the main shaft was replaced by a ring. This revolutionary concept resulted in several patents.

By Ton Bos, co-founder and shareholder of MegaWindForce, The Netherlands

- Details

- Category: Articles

Life-cycle Engineering Asset Management

International research and engineering solutions company TWI Ltd has set its sights on harnessing digital twin technology to transform the process of monitoring and maintaining offshore wind turbines. TWI has built up its knowledge in the structural health and condition monitoring of wind turbines in recent years as a result of its participation in a number of European and UK collaborative projects, including CMSWind, WTBMonitor and TOWERPOWER.

International research and engineering solutions company TWI Ltd has set its sights on harnessing digital twin technology to transform the process of monitoring and maintaining offshore wind turbines. TWI has built up its knowledge in the structural health and condition monitoring of wind turbines in recent years as a result of its participation in a number of European and UK collaborative projects, including CMSWind, WTBMonitor and TOWERPOWER.

By Ángela Angulo, Senior Project Leader, TWI Ltd, UK

- Details

- Category: Articles

District Heating and Cooling with Thermal Storage – A Virtual Battery

District Heating and Cooling with Thermal Storage – A Virtual Battery

Wind energy is becoming a dominant renewable source, providing energy for consumers of electricity, heating and cooling. Unfortunately, few consumers can use the energy directly as the wind blows. We need storage, to avoid loss of energy.

By Anders Dyrelund, Senior Market Manager, and Søren Møller Thomsen, Energy Planner, Ramboll, Denmark

- Details

- Category: Articles

Using Probabilistic Remaining Useful Life Models to Optimise Wind Turbines

Wind turbine asset management is complex, but essential to maximise profits and maintain life cycle costs. The complexity arises for several reasons, including rapid technology development, complex supply chains and constrained infrastructure, remote locations and, more generally, lack of detailed failure data. The goal of asset management is to effectively manage corporate assets to gain maximum value, profitability and returns while safeguarding personnel, the community and the environment. A true asset integrity management programme incorporates design, maintenance, inspection, process, operations and management concepts, since all these disciplines affect the integrity of infrastructure and equipment.

Wind turbine asset management is complex, but essential to maximise profits and maintain life cycle costs. The complexity arises for several reasons, including rapid technology development, complex supply chains and constrained infrastructure, remote locations and, more generally, lack of detailed failure data. The goal of asset management is to effectively manage corporate assets to gain maximum value, profitability and returns while safeguarding personnel, the community and the environment. A true asset integrity management programme incorporates design, maintenance, inspection, process, operations and management concepts, since all these disciplines affect the integrity of infrastructure and equipment.

By Nikhil Kumar, David L. Rogers and Philip Besuner, USA

- Details

- Category: Articles

A Pilot Plant for the Production of Renewable Hydrogen

The pilot plant built within the course of the wind2hydrogen (w2h) research project is the first of this size in Austria and is unique of its kind. The main differences from other projects lie in the chosen type, design and control of the electrolyser as well as the possibility to provide multiple markets with renewable hydrogen. Current and future business cases are simulated in experimental operation from the perspective of the public power grid and the gas grid operator. With this comprehensive approach, reliable statements on the boundary conditions of the power-to-gas technology and future requirements for economic feasibility are expected.

The pilot plant built within the course of the wind2hydrogen (w2h) research project is the first of this size in Austria and is unique of its kind. The main differences from other projects lie in the chosen type, design and control of the electrolyser as well as the possibility to provide multiple markets with renewable hydrogen. Current and future business cases are simulated in experimental operation from the perspective of the public power grid and the gas grid operator. With this comprehensive approach, reliable statements on the boundary conditions of the power-to-gas technology and future requirements for economic feasibility are expected.

By Andreas Zauner and Robert Tichler, Energieinstitut an der Johannes Kepler Universität, Austria