- Category: Articles

Reducing Uncertainty and Cost with Lidar Remote Sensing

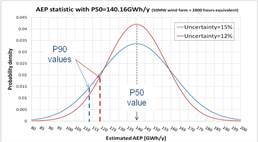

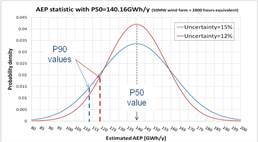

Understanding the wind resource at a prospective project site has long been considered a critical step in the wind farm development process. A wind resource assessment program (WRAP) enables developers to characterise the wind resource and estimate the amount of energy to be produced on an annual basis. The data collected from a WRAP, and the accuracy of that data, drives the success of the project. It determines the feasibility of the project, terms of the Power Purchase Agreement (PPA) with a utility, financing prospects, and even the size and type of turbines placed on site.

Understanding the wind resource at a prospective project site has long been considered a critical step in the wind farm development process. A wind resource assessment program (WRAP) enables developers to characterise the wind resource and estimate the amount of energy to be produced on an annual basis. The data collected from a WRAP, and the accuracy of that data, drives the success of the project. It determines the feasibility of the project, terms of the Power Purchase Agreement (PPA) with a utility, financing prospects, and even the size and type of turbines placed on site.

By Matthieu Boquet, Leosphere SAS, and Evan Osler, NRG Systems

Understanding the wind resource at a prospective project site has long been considered a critical step in the wind farm development process. A wind resource assessment program (WRAP) enables developers to characterise the wind resource and estimate the amount of energy to be produced on an annual basis. The data collected from a WRAP, and the accuracy of that data, drives the success of the project. It determines the feasibility of the project, terms of the Power Purchase Agreement (PPA) with a utility, financing prospects, and even the size and type of turbines placed on site.

Understanding the wind resource at a prospective project site has long been considered a critical step in the wind farm development process. A wind resource assessment program (WRAP) enables developers to characterise the wind resource and estimate the amount of energy to be produced on an annual basis. The data collected from a WRAP, and the accuracy of that data, drives the success of the project. It determines the feasibility of the project, terms of the Power Purchase Agreement (PPA) with a utility, financing prospects, and even the size and type of turbines placed on site.By Matthieu Boquet, Leosphere SAS, and Evan Osler, NRG Systems

- Category: Articles

Strategies to Keep Them Turning

The SCADA alarm flashes red as the blades slowly come to a stop. The site manager gets a call – what now? A generator is failing. Again. Sadly, this scenario plays out somewhere in North America every day of the year. Why is this happening and what can be done? Generators stop working for several reasons and, of course, it might be an unforeseen design flaw, but most failures are both predictable and preventable. With proper cause analysis combined with good planning and execution of maintenance procedures, the failure rates could be cut by almost 50%. In addition, serial defects due to non-optimised designs or poor installation can be managed and solved efficiently once discovered.

The SCADA alarm flashes red as the blades slowly come to a stop. The site manager gets a call – what now? A generator is failing. Again. Sadly, this scenario plays out somewhere in North America every day of the year. Why is this happening and what can be done? Generators stop working for several reasons and, of course, it might be an unforeseen design flaw, but most failures are both predictable and preventable. With proper cause analysis combined with good planning and execution of maintenance procedures, the failure rates could be cut by almost 50%. In addition, serial defects due to non-optimised designs or poor installation can be managed and solved efficiently once discovered.

By Kevin Alewine, Director of Renewable Energy Services, Shermco Industries, USA

The SCADA alarm flashes red as the blades slowly come to a stop. The site manager gets a call – what now? A generator is failing. Again. Sadly, this scenario plays out somewhere in North America every day of the year. Why is this happening and what can be done? Generators stop working for several reasons and, of course, it might be an unforeseen design flaw, but most failures are both predictable and preventable. With proper cause analysis combined with good planning and execution of maintenance procedures, the failure rates could be cut by almost 50%. In addition, serial defects due to non-optimised designs or poor installation can be managed and solved efficiently once discovered.

The SCADA alarm flashes red as the blades slowly come to a stop. The site manager gets a call – what now? A generator is failing. Again. Sadly, this scenario plays out somewhere in North America every day of the year. Why is this happening and what can be done? Generators stop working for several reasons and, of course, it might be an unforeseen design flaw, but most failures are both predictable and preventable. With proper cause analysis combined with good planning and execution of maintenance procedures, the failure rates could be cut by almost 50%. In addition, serial defects due to non-optimised designs or poor installation can be managed and solved efficiently once discovered.By Kevin Alewine, Director of Renewable Energy Services, Shermco Industries, USA

- Category: Articles

An Alternative to Rotary Wind Systems

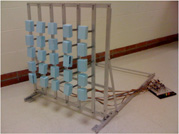

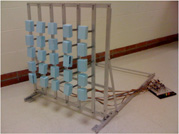

‘Vibro-wind’ denotes the harvesting of energy from the wind as it flows around vibrating structures and is an emerging alternative to conventional rotary wind turbines. The basic science involves wind-induced vibration due to the non-linear fluid flow and vortices around flexible bodies and structures. Two key problems in this technology are: (1) how to convert wind energy into vibratory mechanical energy and (2) how to maximise mechanical energy conversion into electrical energy and storage from the vibration of a large array of hundreds of oscillators. A target application is for architectural facades in buildings, similar to, and as a complement to, solar energy panels.

‘Vibro-wind’ denotes the harvesting of energy from the wind as it flows around vibrating structures and is an emerging alternative to conventional rotary wind turbines. The basic science involves wind-induced vibration due to the non-linear fluid flow and vortices around flexible bodies and structures. Two key problems in this technology are: (1) how to convert wind energy into vibratory mechanical energy and (2) how to maximise mechanical energy conversion into electrical energy and storage from the vibration of a large array of hundreds of oscillators. A target application is for architectural facades in buildings, similar to, and as a complement to, solar energy panels.

By Francis C. Moon, Sibley School of Mechanical and Aerospace Engineering, Cornell University, USA

‘Vibro-wind’ denotes the harvesting of energy from the wind as it flows around vibrating structures and is an emerging alternative to conventional rotary wind turbines. The basic science involves wind-induced vibration due to the non-linear fluid flow and vortices around flexible bodies and structures. Two key problems in this technology are: (1) how to convert wind energy into vibratory mechanical energy and (2) how to maximise mechanical energy conversion into electrical energy and storage from the vibration of a large array of hundreds of oscillators. A target application is for architectural facades in buildings, similar to, and as a complement to, solar energy panels.

‘Vibro-wind’ denotes the harvesting of energy from the wind as it flows around vibrating structures and is an emerging alternative to conventional rotary wind turbines. The basic science involves wind-induced vibration due to the non-linear fluid flow and vortices around flexible bodies and structures. Two key problems in this technology are: (1) how to convert wind energy into vibratory mechanical energy and (2) how to maximise mechanical energy conversion into electrical energy and storage from the vibration of a large array of hundreds of oscillators. A target application is for architectural facades in buildings, similar to, and as a complement to, solar energy panels.By Francis C. Moon, Sibley School of Mechanical and Aerospace Engineering, Cornell University, USA

- Category: Articles

New Development Secures Achievement of Requested Emergency Pitch Stroke

AVN Energy has developed a dynamic simulation model that can be used to verify the performance of its hydraulic pitch systems. The basic idea of the program is to facilitate pitch simulation with user-specific parameters in order to simulate the physical and environmental conditions of a wind turbine. Using this newly developed simulation program users can investigate if the accumulators, cylinders and valves have the correct dimensions in proportion to each other and thus can always achieve the requested emergency pitch stroke.

AVN Energy has developed a dynamic simulation model that can be used to verify the performance of its hydraulic pitch systems. The basic idea of the program is to facilitate pitch simulation with user-specific parameters in order to simulate the physical and environmental conditions of a wind turbine. Using this newly developed simulation program users can investigate if the accumulators, cylinders and valves have the correct dimensions in proportion to each other and thus can always achieve the requested emergency pitch stroke.

By Ea Dyrbye, Marketing Project Manager, and Søren Stubkier, Industrial Researcher, AVN Energy A/S, Denmark

AVN Energy has developed a dynamic simulation model that can be used to verify the performance of its hydraulic pitch systems. The basic idea of the program is to facilitate pitch simulation with user-specific parameters in order to simulate the physical and environmental conditions of a wind turbine. Using this newly developed simulation program users can investigate if the accumulators, cylinders and valves have the correct dimensions in proportion to each other and thus can always achieve the requested emergency pitch stroke.

AVN Energy has developed a dynamic simulation model that can be used to verify the performance of its hydraulic pitch systems. The basic idea of the program is to facilitate pitch simulation with user-specific parameters in order to simulate the physical and environmental conditions of a wind turbine. Using this newly developed simulation program users can investigate if the accumulators, cylinders and valves have the correct dimensions in proportion to each other and thus can always achieve the requested emergency pitch stroke.By Ea Dyrbye, Marketing Project Manager, and Søren Stubkier, Industrial Researcher, AVN Energy A/S, Denmark

- Category: Articles

Small is Sometimes Better

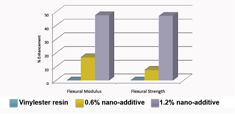

Wind turbine blade manufacturers are being challenged to build larger and larger blades, exhausting the capabilities of current composite materials. The emerging field of nanotechnology will offer dramatic benefits for composites applications. This article introduces the reader to the unique properties of nanoparticles, and why their small size is important. The technical hurdles for nanomaterials are addressed and an example of how nanomaterials can improve the performance of materials is given.

Wind turbine blade manufacturers are being challenged to build larger and larger blades, exhausting the capabilities of current composite materials. The emerging field of nanotechnology will offer dramatic benefits for composites applications. This article introduces the reader to the unique properties of nanoparticles, and why their small size is important. The technical hurdles for nanomaterials are addressed and an example of how nanomaterials can improve the performance of materials is given.

By Blake Branson, President, Chief Science Officer, sp3 nanotech, USA

Wind turbine blade manufacturers are being challenged to build larger and larger blades, exhausting the capabilities of current composite materials. The emerging field of nanotechnology will offer dramatic benefits for composites applications. This article introduces the reader to the unique properties of nanoparticles, and why their small size is important. The technical hurdles for nanomaterials are addressed and an example of how nanomaterials can improve the performance of materials is given.

Wind turbine blade manufacturers are being challenged to build larger and larger blades, exhausting the capabilities of current composite materials. The emerging field of nanotechnology will offer dramatic benefits for composites applications. This article introduces the reader to the unique properties of nanoparticles, and why their small size is important. The technical hurdles for nanomaterials are addressed and an example of how nanomaterials can improve the performance of materials is given.By Blake Branson, President, Chief Science Officer, sp3 nanotech, USA

- Category: Articles

A Guide to Standards

Surge protection is a field of knowledge all on its own, which is becoming both larger and more important to the wind industry as it becomes more common to try to design a thorough system of protection against over-voltages. This has become especially relevant as cost-conscious companies increasingly focus on the wear caused by surge events to electrical and electronic components.

By Thomas Holm Krogh, Consulting Engineer, Electricon A/S, Denmark

Surge protection is a field of knowledge all on its own, which is becoming both larger and more important to the wind industry as it becomes more common to try to design a thorough system of protection against over-voltages. This has become especially relevant as cost-conscious companies increasingly focus on the wear caused by surge events to electrical and electronic components.

By Thomas Holm Krogh, Consulting Engineer, Electricon A/S, Denmark

- Category: Articles

Wind Turbines and Air Traffic Contol

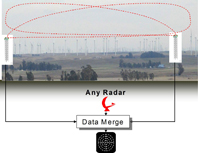

Throughout the world, wind turbines are rapidly becoming a widespread feature of landscapes, because of efforts to reduce dependence on fossil fuels, spurred on by presidential mandates and global agreements. Air traffic control radars are just one of many types of radar that are being directly affected by the proliferation of wind turbines in the environment, and Raytheon is one of the leading companies addressing the issue of wind turbine and radar coexistence.

Throughout the world, wind turbines are rapidly becoming a widespread feature of landscapes, because of efforts to reduce dependence on fossil fuels, spurred on by presidential mandates and global agreements. Air traffic control radars are just one of many types of radar that are being directly affected by the proliferation of wind turbines in the environment, and Raytheon is one of the leading companies addressing the issue of wind turbine and radar coexistence.

By Peter Drake, Raytheon Company, USA, and Brian Smith, Raytheon Canada Ltd

Throughout the world, wind turbines are rapidly becoming a widespread feature of landscapes, because of efforts to reduce dependence on fossil fuels, spurred on by presidential mandates and global agreements. Air traffic control radars are just one of many types of radar that are being directly affected by the proliferation of wind turbines in the environment, and Raytheon is one of the leading companies addressing the issue of wind turbine and radar coexistence.

Throughout the world, wind turbines are rapidly becoming a widespread feature of landscapes, because of efforts to reduce dependence on fossil fuels, spurred on by presidential mandates and global agreements. Air traffic control radars are just one of many types of radar that are being directly affected by the proliferation of wind turbines in the environment, and Raytheon is one of the leading companies addressing the issue of wind turbine and radar coexistence.By Peter Drake, Raytheon Company, USA, and Brian Smith, Raytheon Canada Ltd

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.