Root Cause Hypotheses and How to Prevent Failures

The failure of bearings due to the development of white-etching cracks (WEC) in the inner ring of the bearing has become a leading cause of wind turbine gearbox unreliability. The failures are not confined to any single gearbox or bearing manufacturer, but are systemic throughout the industry. The root cause of the failures is not known, although many theories have been proposed and are currently under investigation. Even though the cause of failures is not well understood, risk factors that make a bearing more prone to experience WEC failures are known, as are factors that make a bearing less prone to these failures. By following some simple best practice guidelines in the selection of bearings, WEC bearing failures can be minimised or prevented altogether.

The failure of bearings due to the development of white-etching cracks (WEC) in the inner ring of the bearing has become a leading cause of wind turbine gearbox unreliability. The failures are not confined to any single gearbox or bearing manufacturer, but are systemic throughout the industry. The root cause of the failures is not known, although many theories have been proposed and are currently under investigation. Even though the cause of failures is not well understood, risk factors that make a bearing more prone to experience WEC failures are known, as are factors that make a bearing less prone to these failures. By following some simple best practice guidelines in the selection of bearings, WEC bearing failures can be minimised or prevented altogether.

By Rob Budny, President, RBB Engineering, USA

Background on WEC Failure Mode

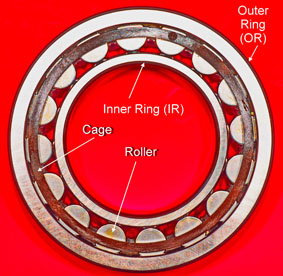

WEC failures are a relatively recent phenomenon, and can occur at stress levels much lower than those required to cause ‘classical’ rolling contact fatigue. WEC failures were first observed in the automotive industry in the 1990s. The failures occurred in alternator bearings, and the failure rates and consequences of failure were both much lower than what is seen in wind turbine gearboxes today. The components of a cylindrical roller bearing are shown and labelled in Figure 1. The WEC failure mode occurs most often in the inner ring of a bearing. The reasons for this are twofold: