It will be marvellous from a sustainability viewpoint to see wind turbine blades being recyclable and recycled. A survey of various wind turbine manufacturers indicates that presently between 85% and 90% (by weight) of decommissioned, or out-of-service, wind turbine materials are recycled. This involves mostly metals such as steel and copper and those in the electronic components. What is not included in this figure is the composite material, mainly in the wind turbine blades and to a lesser extent the nacelle roof/cover. Unfortunately, so far turbine blades ended up in landfills, a graveyard that cannot be supported and maintained as more and larger units will need to be accommodated.

By Ahmad Hemami, McGill University, Montreal, Canada

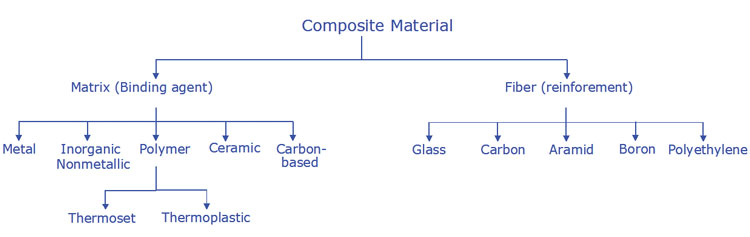

The main reason for not recycling wind turbine blades has been the fact that they are made of composite material. Despite their advantages such as mechanical strength and light weight, recycling of composite materials has been a challenge, particularly for certain combinations of the binding agent (called matrix), which is a resin, and the reinforcement component (called the constituent material), which is in the form of fibre. Figure 1 shows the various materials used for matrix and reinforcement.

Wind turbine blades are mainly made of carbon fibre reinforced polymers (CFRPs) and glass fibre reinforced polymers (GFRPs), which offer durability and a high strength-to-weight ratio. The reason for making turbine blades from composite material is because they must be light but strong; also, they contain relatively little material (being hollow) at relatively low manufacturing costs. However, separating the components is a challenging task due to thermoset-based resins. As a result, recycling turbine blades is not possible (or better said, has not been possible so far) due to a technological issue. For more information on recycling composite materials there are plenty of resources, such as [1] and [2].

In general, a number of conditions govern if recycling of any manufactured object is practical. These are:

- Technical aspects

- Cost

- Application (Need for the recycled material)

It is obvious that all these conditions must be met. For instance, if the cost of recycled substance is too high compared to the cost of virgin material, companies are not interested in recycling, unless required by the policymakers. Also, if not enough application (usage) for the recovered material exists, then there will not be any motivation to do that. In this respect, for wind turbine blades, even if they could be recycled, if sufficient usage could not be found, then the extras would still end up in landfills.

An application for a recycled material can be of a secondary nature, particularly if degraded, for instance using crushed composite material for pavement surface (GE turbines), or as practised by Goldwind, employing crushed blades for 3-D printing of containers (for flower beds, for example). However, another question arises here: from a health point of view, whether the dust from composite materials, when used as something that can wear and erode (asphalt, for instance), is harmful to people.

For wind turbine blades there have been very little (ignorable) secondary applications, like using pieces from cut blades in parks and recreational activities. Nonetheless, one can think of many other applications like using the pieces of turbine blades as beams for construction, walls and fences. For these sorts of usages, it is not necessary to crush a blade into very small pieces, but a lot of regular forms must be cut out of an irregular form blade. Thus, there are plenty of leftovers that must be crushed for other purposes. The very best usage of turbine blades is if they can be used for manufacturing new blades.

Similar to research on composite materials there has been tremendous research going on devoted to turbine blade recycling. A comprehensive review and listing of the articles on the subject can be found in [3].

The various techniques for separation of components in composite materials are

1 Mechanical recycling

2 Thermal recycling:

a) Fluidised-bed combustion recycling

b) Pyrolysis recycling

3- Chemical recycling

The titles suggest the process used: mechanical recycling involves breaking the blade into tiny pieces by grinding/milling and sieving the product. To some extent, thermal and chemical recycling also needs crushing a blade. Thermal recycling involves heating the material to a high temperature to burn the resin (fluidised-bed combustion recycling), or to separate the resin from the fibre in the form of a liquid (pyrolysis recycling).

Pyrolysis needs to be done at high temperatures of 300–800◦C in the absence of oxygen. Both glass and carbon fibre reinforced composites can be recycled through this process. But because of the much higher market value of carbon fibres, pyrolysis recycling of carbon fibre reinforced composites is more economically feasible.

Chemical recycling involves the process of chemically removing the matrix by using dissolution reagents for liberation of fibres. It can regenerate both clean fibres and fillers as well as depolymerised matrix.

Recyclable blades were first introduced by Siemens Gamesa Renewable Energy [4], and the first recyclable blades were installed in 2021. This was followed by Mingyang Smart Energy in 2023 for their recyclable blade. In both cases the resin was changed. Other manufacturers have this task in their future plans.

Further reading

- A. A. van Oudheusden, “Recycling of composite materials”: Recycling of composite materials | TU Delft Repository (https://repository.tudelft.nl/record/uuid:0749ed5c-7aeb-4275-abee-0f904a08ea4d)

- Yongxiang Yang et all, “Recycling of composite materials”, Chemical Engineering and Processing: Process Intensification, Volume 51, January 2012, Pages 53-68 (https://www.sciencedirect.com/science/article/abs/pii/S0255270111002029)

- Muhammad Yasir Khalid, et al. “Recycling of wind turbine blades through modern recycling technologies: A road to zero waste”, Renewable Energy Focus, Volume 44, March 2023, Pages 373-389 (https://www.sciencedirect.com/science/article/abs/pii/S1755008423000121)

- https://www.siemensgamesa.com/global/en/home/explore/journal/recyclable-blade.html