Increasing Net Electricity and Profit

Increasing Net Electricity and ProfitBy simply placing slots on the bottom of the trailing edge of wind blade tips, a ‘blown flap’ may be created, increasing lift by a significant factor. This could result in 1 to 25% more net electricity, or $ 1–25 billion more net profit per year for the wind industry.

By Mike Fritz, USA

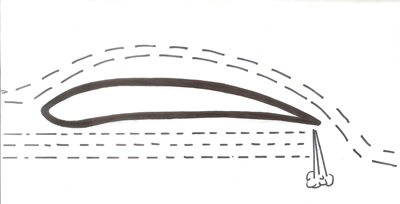

As the wind blade rotates, the centrifugal force inside throws the air molecules to the end of the blade.

The interior air is then compressed. Next it shoots the air out of slots located on the trailing edge of the blades, in the tip region. The jet force shoots out of the slots in the opposite direction to the desired lift.

This causes lift in two ways:

1) The ‘rocket blast effect’. This is simply applying the law, ‘To every action there is an equal and opposite reaction.’

2) By acting as an invisible airplane wing’s flap.

1) The ‘rocket blast effect’. This is simply applying the law, ‘To every action there is an equal and opposite reaction.’

2) By acting as an invisible airplane wing’s flap.

This invisible wind blade flap has another benefit. Since it is not physically connected to the wind blade, it develops no drag. Lift without drag!

This invisible wind blade flap has another benefit. Since it is not physically connected to the wind blade, it develops no drag. Lift without drag!According to Wikipedia, a blown flap increases lift in airplanes, like the F-4 Phantom jet fighter, by a factor of 2 to 3 times. It seems pretty obvious that if you increase the lift of the third of the wing containing the tip by that amount, you will increase the overall efficiency significantly.

One cubic metre of air weighs approximately 1.293kg. At the end of a wind blade of 84 metres rotating at 12 rpm, one cubic metre will weigh more than 2,000kg.

As the angle of attack of the wind blade and its speed increase, the blown flap will increase in pressure but decrease in relative size, while the relative improvement in the overall efficiency is retained.

Especially important are the slots at the very end of the tip, where high pressure meets low pressure. In airplane wings the wing tips produce a vortex. This is a cause of drag slowing the airplane down. Some pilots report a gas saving of up to 15% by installing, on the end of their wings, tip tanks to destroy this vortex created drag.

The blown flap tip invention should increase the net overall efficiency of a wind turbine generator (WTG) by 10–25% for only the cost of adding a few holes in each wind blade tip. If all the WTGs in the world were to convert to this technology, this could result in $ 8–25 billion additional net profit for the wind industry, and its players, every year.

Z-333 has not yet decided whether to patent this invention. However, any Windtech International readers that inform Z-333 in writing within 3 months of this publication that they would like to use it without cost may use it for free regardless of whether we patent and license it soon or not.

Contact:

Z-333 Windmill Werks, Attn: Jim Fritz

PO Box 427

Great Cacapon, WV,

USA 25422-0427

PO Box 427

Great Cacapon, WV,

USA 25422-0427

mike_j_fritz @ hotmail.com