- Details

- Category: Articles

Evaluating Ageing Turbines for Safe Operation Beyond Their Design Lives

Evaluating Ageing Turbines for Safe Operation Beyond Their Design LivesAn increasing number of wind turbines are approaching the end of their service lives. As a result, operators are being confronted with the crucial business decision of whether to decommission, repower or continue to operate their assets. One of the key factors affecting these decisions is the evaluation of the physical condition of the turbine considered for continued operation. In this article, TÜV SÜD describes the methods, requirements and results of a lifetime extension assessment.

By Christian Schumacher and Florian Weber, TÜV SÜD Industrie Service, Germany

- Details

- Category: Articles

New Polyurethane Resin for Wind Turbine Blades Outperforms Epoxy Resin

New Polyurethane Resin for Wind Turbine Blades Outperforms Epoxy ResinA new polyurethane (PU) resin developed by Covestro, a supplier of high-tech polymer materials, enhances wind blade production through faster infusion and curing speeds. More efficient production of rotor blades in turn lowers production costs. Moreover, this new resin enables the production of lighter, longer and stronger blades with a higher energy output. WINDnovation, a designer of rotor blades, recently carried out a study in China. The study revealed that Covestro’s PU resin meets all performance requirements and actually outperforms the commonly used epoxy resin. In other words, this newly developed PU resin meets the challenge the industry faces of enabling the long-term expansion of wind energy through reducing the cost of this renewable power.

By Yongming Gu, Head of Composite Application Development of PUR APAC, Covestro Shanghai Polymer R&D Center, China

- Details

- Category: Articles

Optimisation of Spherical Roller Bearings

Optimisation of Spherical Roller BearingsWhat began as mere windmills in the 1970s, barely able to generate 0.05MW of power, have matured into today’s modern wind turbines that are capable of producing more than 7.0MW each, with offshore prototypes attaining an output of as much as 12MW. Inside these high-performance machines, the rotor shaft bearing support is a vital component where the locating bearing is subjected to particularly high loads. These unique application conditions, combined with stringent reliability requirements and increasing incidents of failed bearings in the field, provided the impetus for an engineering project whereby Schaeffler set out to optimise the spherical roller bearings that are used as wind turbine main shaft bearings.

By Antonio Silverio and Anant Bhat, Schaeffler Group USA Inc.

- Details

- Category: Articles

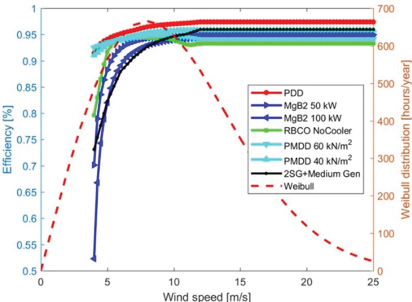

Growth of Installed Capacity

Growth of Installed CapacityRecent forecasts from the International Energy Agency (Offshore Wind Outlook 2019) and the International Renewable Energy Agency (IRENA, Future of Wind) suggest that offshore wind will grow dramatically. The IRENA report is especially bullish, suggesting annual installed capacity will grow from 4.5GW/y in 2018 to 45GW/y by 2050. This is slightly higher than the Offshore Wind Outlook 2019, which expects annual installations to reach 40GW/y by 2040.

By David Latimer, CEO, Magnomatics, UK

- Details

- Category: Articles

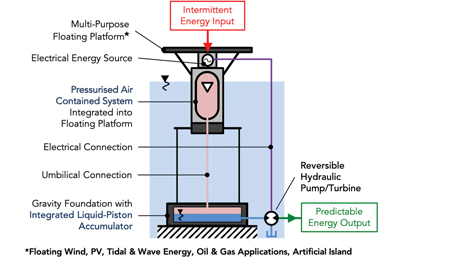

A Sustainable Solution for Offshore Wind

A Sustainable Solution for Offshore WindEnergy storage technologies will be crucial in overcoming one of the most challenging barriers to high renewable energy penetration, i.e. the mismatch between renewable energy supply and consumer demand. Ongoing work is focused on the development of a hydropneumatic energy storage technology, tailored for offshore applications, referred to as FLASC. Whether connecting offshore renewables to onshore grids or to energy-intensive oil and gas infrastructure, the technology is designed to act as an energy buffer, eliminating intermittency and delivering a schedulable energy output. The technology itself combines pressurised seawater and compressed air in a liquid piston embodiment. It avoids hazardous chemicals and is designed for a long lifetime (+25 years), independent of the charging/discharging regime. A small-scale prototype was deployed in the Grand Harbour of the central Mediterranean island of Malta. Having completed over 300 charging cycles, the prototype is the ultimate proof of concept of the technology and sets the foundation for future development leading to commercial applications.

By Daniel Buhagiar, Co-Founder FLASC and Postdoctoral Researcher, University of Malta

- Details

- Category: Articles

Drone-Borne Magnetic Technologies Provide New Opportunities for Mapping of UXO

Clearing of unexploded ordnance (UXO) is critical for the safe construction of offshore wind farms in old war zones. While most UXO is ferrous, the preferred mapping technique is by magnetic sensors. These are towed behind vessels in the offshore area, while a combination of small survey boats, all-terrain vehicles and walking personnel are often used to cover the near- and onshore cable landing point area. However, intertidal zones, such as the edges around the North Sea, are notoriously difficult to access by traditional mapping platforms. As a consequence, mapping of intertidal UXO is often incomplete and imprecise, which causes delays during the UXO clearing operation or, worse, safety issues and delays once the construction of the wind farm has begun. In this article, we present a case study by UMag Solutions and Ørsted from Hornsea II in the UK and explain the power of drone-borne magnetic mapping of intertidal UXO.

Clearing of unexploded ordnance (UXO) is critical for the safe construction of offshore wind farms in old war zones. While most UXO is ferrous, the preferred mapping technique is by magnetic sensors. These are towed behind vessels in the offshore area, while a combination of small survey boats, all-terrain vehicles and walking personnel are often used to cover the near- and onshore cable landing point area. However, intertidal zones, such as the edges around the North Sea, are notoriously difficult to access by traditional mapping platforms. As a consequence, mapping of intertidal UXO is often incomplete and imprecise, which causes delays during the UXO clearing operation or, worse, safety issues and delays once the construction of the wind farm has begun. In this article, we present a case study by UMag Solutions and Ørsted from Hornsea II in the UK and explain the power of drone-borne magnetic mapping of intertidal UXO.By Arne Døssing Andreasen, CEO, UMag Solutions, Denmark

- Details

- Category: Articles

How Do We Determine Optimal Inspection Frequency?

How Do We Determine Optimal Inspection Frequency?The old adage that an ounce of prevention is worth a pound of cure – a 16-fold return on investment in this case – is severely conservative when it comes to maintenance of wind turbine rotor blades. The cost of repairing early-stage damage – or even better, implementing remediation solutions for serial issues before damage occurs in most blades – is often minuscule compared with the cost of a single catastrophic failure. Within the next few years, the industry must evolve to a practice of routine scheduled inspections followed by proactive repair and remediation in order to minimise the life-cycle cost of ownership.

By Dr Kyle Wetzel, Vice President Blade Services, SkySpecs, USA

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.