Providing Quality Assurance Over the Lifetime

The standard inspection method for quality assurance of the exterior surfaces of wind turbines is to employ people trained as rope access or industrial climbers. But this is not the only way. This article, by Robert Hörmann of Aero Enterprise in Austria, outlines (using his company’s products) how drones can undertake visual inspection of turbines, and then supporting software and archiving can be used to analyse the data. As the author admits, drones and airborne access will never be a complete substitute for manned inspection, and there will always be the need for rope access workers, but he shows that there are many advantages to drone-based inspection together with software analysis and archiving.

The standard inspection method for quality assurance of the exterior surfaces of wind turbines is to employ people trained as rope access or industrial climbers. But this is not the only way. This article, by Robert Hörmann of Aero Enterprise in Austria, outlines (using his company’s products) how drones can undertake visual inspection of turbines, and then supporting software and archiving can be used to analyse the data. As the author admits, drones and airborne access will never be a complete substitute for manned inspection, and there will always be the need for rope access workers, but he shows that there are many advantages to drone-based inspection together with software analysis and archiving.

By Robert Hörmann, CEO/CTO and Founder of Aero Enterprise, Austria

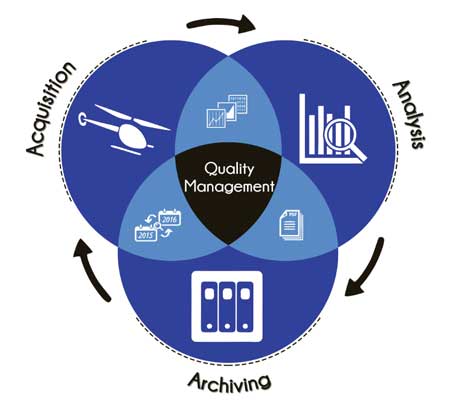

Aero Enterprise GmbH, a young company located in Linz, Austria, is active in the field of airborne quality assurance. The company was founded in 2013 and provides its service with a comprehensive system consisting of a helicopter-type flight-robot (drone) called SensorCopter, client-based analysis software, AERO-Lyse, and a database where all the gathered data is stored. Data mining and machine learning tools enable clients to use the data not only for statistics about the present state of the turbine but to predict upcoming demand for maintenance. Customers are operators of wind farms, service companies, insurance companies and OEMs, as well as technical experts in this field. The technology can be applied to all kinds of vertical objects and helps to reduce maintenance and long-term aftersales costs.