When talking about wind turbines and the cost of wind energy, the scenario that comes to mind is an onshore or offshore wind farm that captures power from wind and injects it into a grid. That is, wind power is used according to:

Scenario 1: Wind energy is generated at point A and transmitted via a high-voltage line to point B.

The costs involved in this scenario are those of the wind farm development and accessing the high-voltage line, the cost of which is not often a part of the associated expenditure.

By Ahmad Hemami, McGill University, Montreal, Canada

The progress made in wind technology and the efforts made in recent years to bring down the cost to make it compatible with the energy from coal and other fossil fuels has led to the following statement in the ‘Global Offshore Wind Report 2023’ by the Global Wind Energy Council:

‘After a decade of cost reductions, offshore wind is at an inflection point with a highly competitive levelised cost of electricity (LCOE) that is $3/MWh below that of coal and $18/MWh below that of gas.’

Comparing wind and oil does not seem to be a reasonable thing to do because of their many differences. Wind is a low-gradient source of energy. It is plentiful, free and there is no cost for its exploration. The cost of evaluation of a site for good wind is much smaller than the exploration cost for the discovery of an oilfield. Exploring a sedimentary basin to discover an oilfield is very cost intensive.

However, after hearing about the Canada–Germany Hydrogen Alliance, a different scenario – which could be a regular practice in the future of wind energy – comes to mind. Based on this practice, energy from wind in Atlantic Canada is used to generate liquid hydrogen, which is shipped to Germany in tankers for consumption. This scenario is not far from the one practiced for oil. The scenario is as follows:

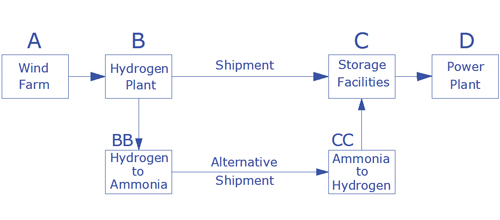

Scenario 2: Wind energy is grasped at point A and converted to electricity; at point B the generated electricity is used to produce hydrogen, which is transported to point C, where it is used to provide fuel to generate electricity at point D (Figure 1).

Assuming there is not much distance between points A and B, the additional costs involved in this compared with scenario 1 are:

(a) the plant for making hydrogen

(b) transportation of liquid hydrogen (from the exporting facility at point B to the importing facility at point C)

(c) hydrogen storage at points B and C

(d) transportation of hydrogen fuel from point C to D

(e) power station at point D.

There are various ways of producing hydrogen from different sources, but with electricity being a principal ingredient in the process, electrolysis of water is the best choice. Furthermore, hydrogen as a fuel can be used in two main ways (presently at a small scale, like vehicles): in the form of a fuel cell or through burning – like any other fuel (gasoline, for instance) – in a combustion engine. At the level of a power plant for generating electricity, the former method is not yet practicable. So, we can stick to the latter.

(a) the plant for making hydrogen

(b) transportation of liquid hydrogen (from the exporting facility at point B to the importing facility at point C)

(c) hydrogen storage at points B and C

(d) transportation of hydrogen fuel from point C to D

(e) power station at point D.

There are various ways of producing hydrogen from different sources, but with electricity being a principal ingredient in the process, electrolysis of water is the best choice. Furthermore, hydrogen as a fuel can be used in two main ways (presently at a small scale, like vehicles): in the form of a fuel cell or through burning – like any other fuel (gasoline, for instance) – in a combustion engine. At the level of a power plant for generating electricity, the former method is not yet practicable. So, we can stick to the latter.

For generating hydrogen from electricity, with an efficiency of 100%, 39kWh of electricity is required to produce 1kg of hydrogen. Practically (around 70% efficiency), the number is 55 kWh. The thermal energy generated by burning hydrogen is around 120–140MJ/kg, almost three times more than for diesel or gasoline (44–46 MJ/kg). Thus, the energy density of hydrogen is equal to 33.6 kWh/kg (versus diesel, which only holds about 12–14 kWh/kg). Consequently, compared with a power plant run on liquid fossil fuel, about three times less hydrogen fuel is required for the same amount of energy production.

At this time, there are no figures concerning the installation and running costs of large-scale plants for water electrolysis (to be compared with oil exploration and extraction facilities). Crude oil needs to be refined as well, but this is not a large portion of the fuel cost. The cost of refining crude oil per barrel can fluctuate based on a range of factors. An average range of $ 3 to $ 5 per barrel provides a rough estimate. The capital cost, however, is not insignificant. The investment cost of a completely new refinery depends on its size, complexity and location. It is generally estimated that a 160,000 bbl/d (8 million tons per year) refinery, equipped with catalytic cracking, visbreaking (viscosity reduction) and gasoline units, would cost more than $ 6 billion if built in Europe (2022). The energy contained in a barrel of oil is approximately 5.8 million British thermal units or 1,700 kWh. Thus, such a refinery can prepare fuel for 272,000MWh per day, the equivalent of 90,000MW installed capacity (5,000 units of 18MW turbines).

Nonetheless, the cost of hydrogen transportation is much higher than that of crude oil due to the need for a high-pressure vessel and maintaining the low temperature, which results in both heavier and more expensive tankers for both surface and offshore shipment. Likewise, the storage cost is higher for hydrogen fuel than for oil products for the same reasons. As a result, an alternative deviation may impose a conversion to ammonia and back to hydrogen, just to facilitate and reduce the cost of transportation/storage. The extra costs relevant to this back-and-forth conversion can be associated with the cost of refining crude oil.

Further Reading

- Canada–Germany Hydrogen Alliance: https://natural-resources.canada.ca/climate-change-adapting-impacts-and-reducing-emissions/canadas-green-future/the-hydrogen-strategy/joint-declaration-intent-between-the-government-canada-and-the-government-the-federal/24607

- Global Wind Energy Council. 2023. Global Offshore Wind Report 2023. Belgium. https://gwec.net/wp-content/uploads/2023/08/GWEC-Global-Offshore-Wind-Report-

- The Palgrave Handbook of International Energy Economics. Cham, Switzerland: Palgrave Macmillan. https://doi.org/10.1007/978-3-030-86884-0