The ACT100, the first commercial prototype from ACT Blade, has completed all required tests for component certification. The certification, expected to be issued by UL Solutions in the coming months, marks an important step in the validation of ACT Blade’s technology.

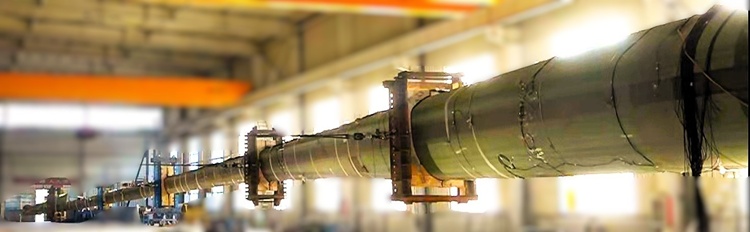

As a component-based wind turbine blade, the ACT100 underwent a series of tests to confirm its structural integrity and performance. These included full-scale testing of the internal composite structure to ensure it can withstand gravitational, aerodynamic, and inertial loads, as well as testing of the lightning protection system. All tests were conducted in accordance with IEC 61400 standards. The final phase of testing, the post-fatigue pull test, was completed in November 2024, with formal documentation released in January 2025.

The certification process has also validated the design of a 49.2-metre blade intended for reblading 2MW turbines, along with ACT Blade’s lightning protection system.

The ACT100 component certification is expected in April 2025. Production has already begun, with the first installation planned for later in the year in southern Italy.

ACT Blade specialises in the development of lightweight, modular wind turbine blades. Its technology features an internal composite structure covered by engineered textile materials. Headquartered in Edinburgh, the company operates a European subsidiary, ACT Blade Europe, with facilities in Naples and Brindisi, Italy, focused on research, development, and manufacturing.

Max load testing of ACT100 wind turbine blade