- Category: Windtech Future

Some time ago, when thinking about the deep sea and transportation of electricity to the shore, it came to my mind that we could possibly use a (huge) battery system which could be charged in a wind farm and then deliver its charge to the onshore grid. Compared with transmission cables, the way that it is right now for all existing wind farms, this is not an ideal solution. Therefore, I set the idea to one side. But with the recent agreement between Canada and Germany, the idea was revived in my mind. If the wind farm is floating on the top of 500 metres or more of water and is far offshore, then the concept is worth being regarded as an alternative. After all, technically and financially, the numbers must be correct and suitable.

Some time ago, when thinking about the deep sea and transportation of electricity to the shore, it came to my mind that we could possibly use a (huge) battery system which could be charged in a wind farm and then deliver its charge to the onshore grid. Compared with transmission cables, the way that it is right now for all existing wind farms, this is not an ideal solution. Therefore, I set the idea to one side. But with the recent agreement between Canada and Germany, the idea was revived in my mind. If the wind farm is floating on the top of 500 metres or more of water and is far offshore, then the concept is worth being regarded as an alternative. After all, technically and financially, the numbers must be correct and suitable.By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

For a comprehensive course in wind energy that I teach, I spend a lot of time updating the numbers for the cost of various turbine components and their percentage of the total cost, as well as the cost of wind farms, for which turbine prices are only one part. As many may know, this is not a straightforward process, since the expenses are case sensitive, and there are no clear-cut figures for this.

For a comprehensive course in wind energy that I teach, I spend a lot of time updating the numbers for the cost of various turbine components and their percentage of the total cost, as well as the cost of wind farms, for which turbine prices are only one part. As many may know, this is not a straightforward process, since the expenses are case sensitive, and there are no clear-cut figures for this.By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

Any new concept in an established manufacturing process or engineering operation will be costly to implement. In most cases it requires research and development, the cost of which must be absorbed by the company behind it. If the concept sounds ‘revolutionary’, at first it might seem either difficult or impossible to achieve. On the other hand, in many industrial applications – out of necessity – research and development is a continuous endeavour to make a product more efficient, have improved performance, cheaper and so on.

Any new concept in an established manufacturing process or engineering operation will be costly to implement. In most cases it requires research and development, the cost of which must be absorbed by the company behind it. If the concept sounds ‘revolutionary’, at first it might seem either difficult or impossible to achieve. On the other hand, in many industrial applications – out of necessity – research and development is a continuous endeavour to make a product more efficient, have improved performance, cheaper and so on.By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

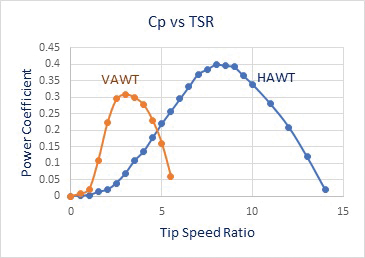

A 2018 publication by Sandia National Laboratories (SNL) [1] indicates that an overall more economical choice of wind turbine for an offshore floating turbine is a vertical axis wind turbine (VAWT). SNL has performed a comprehensive and extensive simulation study using a variety of software for different aspects, from stresses in blades to the levelised cost of energy (LCOE). There are several aspects involved in the design and operation of a wind turbine and even more if it is on a free platform subject to wave forces. In this study, the point of emphasis is the lower LCOE, as a result of smaller platforms for a VAWT, mainly due to the lower centre of gravity compared with a horizontal axis wind turbine (HAWT). This study and others on VAWTs point to the direction of the technology for floating turbines. After all, if the cost of energy is the principal driver for selecting a technology, then a lower LCOE is the preferred choice.

A 2018 publication by Sandia National Laboratories (SNL) [1] indicates that an overall more economical choice of wind turbine for an offshore floating turbine is a vertical axis wind turbine (VAWT). SNL has performed a comprehensive and extensive simulation study using a variety of software for different aspects, from stresses in blades to the levelised cost of energy (LCOE). There are several aspects involved in the design and operation of a wind turbine and even more if it is on a free platform subject to wave forces. In this study, the point of emphasis is the lower LCOE, as a result of smaller platforms for a VAWT, mainly due to the lower centre of gravity compared with a horizontal axis wind turbine (HAWT). This study and others on VAWTs point to the direction of the technology for floating turbines. After all, if the cost of energy is the principal driver for selecting a technology, then a lower LCOE is the preferred choice.By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

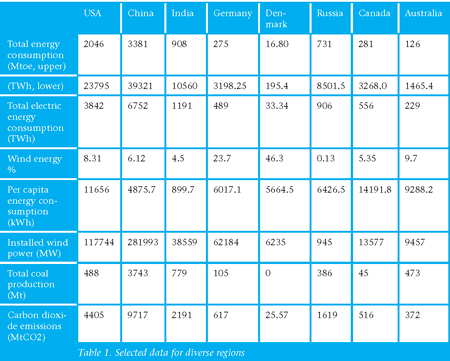

It came to my mind to do some calculations of how many wind turbines we need to power the whole world with renewable energy. Of course, in the future when we run out of fossil fuels, or we are forced not to use fossil fuels any more to survive on Planet Earth, wind will not be the only alternative source of energy. Considering that hydro, wind, solar, wave, geothermal and other renewables may provide say 70–80% of the world’s energy needs in the future, it is reasonable to predict that wind energy will account for over 20%.

It came to my mind to do some calculations of how many wind turbines we need to power the whole world with renewable energy. Of course, in the future when we run out of fossil fuels, or we are forced not to use fossil fuels any more to survive on Planet Earth, wind will not be the only alternative source of energy. Considering that hydro, wind, solar, wave, geothermal and other renewables may provide say 70–80% of the world’s energy needs in the future, it is reasonable to predict that wind energy will account for over 20%.By Ahmad Hemami, McGill University, Montreal, Canada

- Category: Windtech Future

It is likely that many of the people who in one way or another work with wind turbines, the environment and energy know about the good, the bad and the ugly of wind turbines. The good news is that the ugly is expected to become less so.

It is likely that many of the people who in one way or another work with wind turbines, the environment and energy know about the good, the bad and the ugly of wind turbines. The good news is that the ugly is expected to become less so.By Ahmad Hemami, McGill University, Montreal, Canada

- Two Modes of Operation in Back-to-Back Converters for DFIGs, Is It Worthwhile?

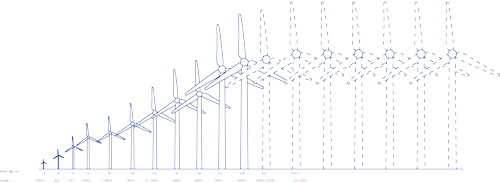

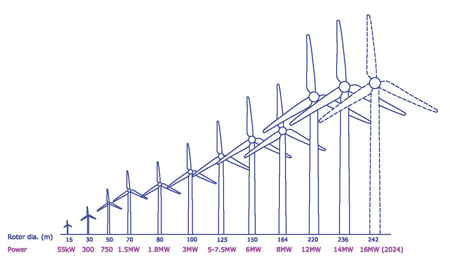

- How Far Will Horizontal Axis Wind Turbines Grow?

- Are We Going in the Right Direction?

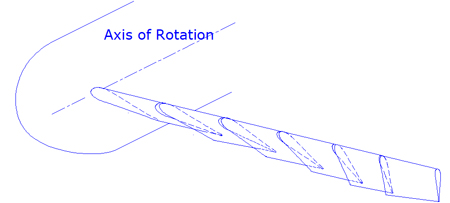

- A Design Concept for Future Offshore Wind Turbines

- Wind Turbines in 2100

- Drones or Robots for Blade Repair?

- Should Offshore Floating Wind Turbines be a Larger Copy of Onshore Turbines?

- The Race for Bigger Turbines Continues

- Why We Need More Green Hydrogen for the Global Energy Transition

- Global Gearbox Supply Chain Market Set to Grow to 59.1GW in 2020

- A New Generation of Offshore Wind Turbine Drive-trains Promises Power Ratings up to 16MW

- Renewable Energy Digital Services Benefits Are Not Fully Recognised

- Wind Energy Industry Has Lost US$ 5.2 billion Through Avoidable IP Infringements and Trade Secret Theft

- Wind Energy Industry Research and Development Spending to Top US$ 36.9 billion by 2028

- Feed-in Tariff Turmoil in Taiwan Will Likely Cause the Offshore Wind Industry to Shift Focus to Nearby South Korea

- OEMs are Shifting Towards Global Supply Chain Cost Optimisation at the Expense of Optimal Turbine Levelised Cost of Energy

- With +10MW Offshore Turbines as the New Normal in Europe, Where Do the Chinese OEMs Go Next?

- Wind LCOE Set to Drop Further Thanks to the Expiration of Seminal Patents

- The Right Product Mix and a Modular Architecture Can Protect OEM Profits in the Age of Tenders

- Renewable Energy Digitalisation Growth Poised to Reap Benefits for the Data Rich

- Turbine OEMs with Product Portfolio Diversity are Most Successful in US Wind Market

- Enercon Acquisition of Lagerwey Enables Competitive Product Evolution with PMG Technology

- Commercial Value of Data Has Increased Thanks to Digitalisation

- Onshore Wind Turbine Tech to Top Out in Ten Years

- Hybrid Materials and 3D Printing Enabling SciFi Wind Turbine Structures

- Can Wireless Mesh Networks Kill Slip-Rings?

- Offshore Wind Yet to See Meaningful Digital Services Deployment

- Focus on TLPs, Predictive Maintenance and AEP Optimisation to Further Reduce Offshore LCOE

- Renewable energy Internet of Things to hit US$ 5.3 billion annually by 2030

- Onerous Mandates on Performance Impact or Reliability are Stifling RE Innovation

- Emergence of Digital Services Highlights Need for Content Licensing Business Model

- Digitalisation Necessitates New Thinking and New Business Models

- How Common Platform Wind Turbine Architecture Unlocks Export Markets

- Closing the Product Competitiveness Gap

- Offshore Innovation Seeing Lift-off

- Consolidation Spurs Wind Innovation Revival

- The future of technology – Services

- Power plant control

- The Rise of Asian Innovation

- The future of technology – Manufacturing

- The future of technology – Materials

Use of cookies

Windtech International wants to make your visit to our website as pleasant as possible. That is why we place cookies on your computer that remember your preferences. With anonymous information about your site use you also help us to improve the website. Of course we will ask for your permission first. Click Accept to use all functions of the Windtech International website.